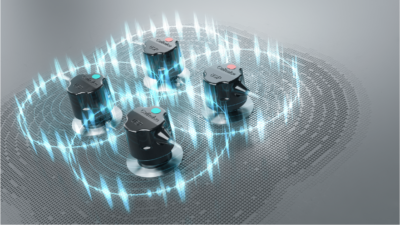

Say hello to Cathelco’s USP DragGone™

Introducing USP DragGone™, the next-generation ultrasonic antifouling solution for superior fuel economy, lower emissions, and a green fleet, all made effortless with our patented technology.

Evac®

A thought leader in sustainable water and waste management.

Cathelco®

Cathelco safeguards your fleet by managing biofouling, ensuring corrosion protection, and generating fresh water

HEM®

HEM offers specialized fresh water generation systems designed to meet the unique requirements of superyachts

Our values

The values describe how we operate and behave as individuals, and how we interact with each other on a day-to-day basis.

In it for the customer

It all starts with our passion, belief in what we do, and pride in solving problems for our customers.

Committed to quality

We strive for best-in-class

service, product excellence, and sustainability in everything we do.

Finding success in collaboration

There are no boundaries

between our teams. We help

each other to deliver the best performance.

Never settle for less

Our work takes courage,

curiosity, and drive. We are accountable and

challenge ourselves to deliver.

Committed to customer success

80%

reduction in carbon emissions with Evac HydroTreat

Evac HydroTreat is not just a ground-breaking innovation for the cruise industry, but for waste management in general. It’s a game changer in the whole circular economy process.

150

patents to support our customers in exceeding their regulatory requirements

Evac is a great partner and a very innovative company. They listen to our intentions and understand how we are always trying to go a bit further to solve onboard waste problems and prevent discharging at sea. We cooperate closely to exchange ideas to improve the technology even more.

90%

water saving in vacuum toilets compared to standard ones

Cicignon Park will set a new standard for future blue-green development following the UN’s sustainability goals. Selecting Evac’s vacuum technology as the drainage solution is fully aligned with our sustainable development plans.

Evac is trusted by global companies in maritime and land-based industries

Be part of the movement