Hull antifouling methods: Choosing the best antifouling option for modern fleets

Antifouling a ship’s hull can extend the life of your fleet, improve operating efficiency, and save on operational costs. It helps slow corrosion and prevents marine organisms from attaching to the hull and reaching the ship’s critical interior components.

Various antifouling methods slow the growth of marine organisms on your hulls. When left untreated, slime, seaweed, barnacles, and other aquatic life accumulate on your hull, slowing the ship and reducing fuel efficiency. Sticking to a marine growth prevention routine helps reduce your climate impact while ensuring uninterrupted operations.

It’s crucial to select the right antifouling method for your needs. Consider the number of vessels you operate, their size, and how long each method lasts before you must repeat the process. Next, determine how each method would impact your operations and select the best fit for your vessel’s operating profile.

Coatings and paints

Antifouling coatings and paints are a common antifouling measure used on ships of all sizes. These coatings and paints are made with ingredients such as copper, arsenic, and other agents that repel marine growth. To apply antifouling paint or coatings, you need to clean and dry the hull. Next, choose a product. Soft antifoul will wear away over time, while hard antifoul is scrubbable. With a hard antifoul, you can scrub the hull, which is more appropriate for higher-speed vessels. Some products last longer than others. Before you choose an antifouling paint or coating, review the manufacturer’s recommendations to determine how often you need to reapply.

Pros of antifouling coatings and paints

Paints and coatings effectively protect your vessels from substrate damage. They can also help make your hull more durable and scratch resistant. Because there are many options available, this can be a lower-cost antifouling technique. You will likely pay a high upfront cost for paint or coatings designed to last for multiple seasons. However, you won’t have to take your ships out of service as often with this option.

Potential cons of antifouling coatings and paints

Depending on their composition, some antifouling paints and coatings no longer comply with environmental regulations. Heavy metals and other compounds in paints and coatings are toxic to marine life. One such biocide, organotin compound tributyltin (TBT), causes defects in some aquatic animals. Over time, paint and coatings leach these chemicals into the ocean. Some paints also flake off, releasing toxins. As a result, governments worldwide have created guidelines to help minimize their environmental impact. Additionally, some soft coatings are easily scratched, making your vessel more susceptible to corrosion.

Ultrasonic antifouling

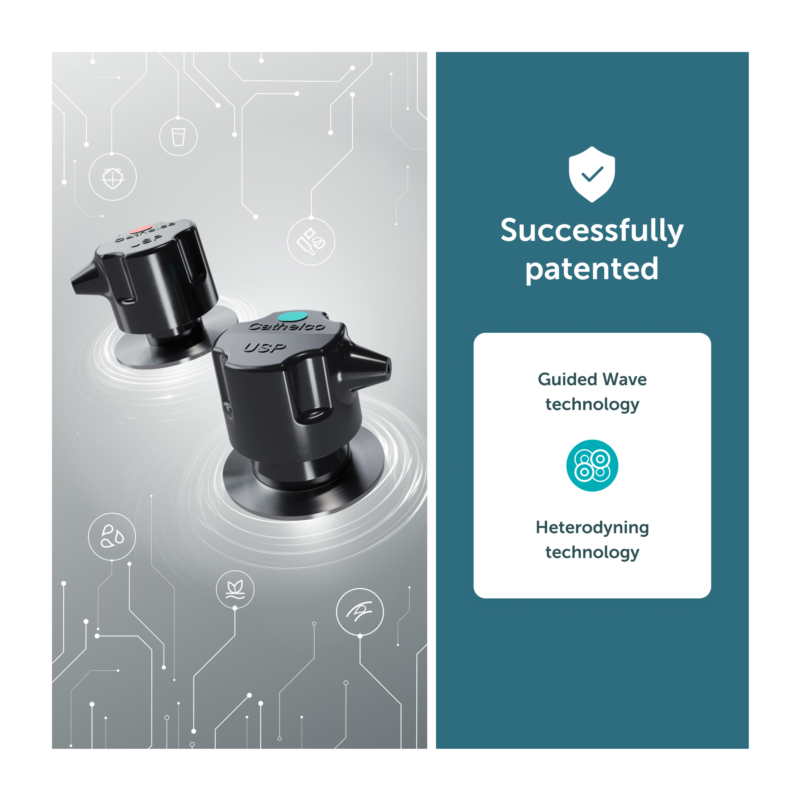

If you’re looking for an eco-friendlier and proactive antifouling option, consider ultrasonic antifouling. These systems emit high-frequency sound waves that prevent algae and other microorganisms from accumulating on your ship’s hull. With no initial fouling biofilm, barnacles, mussels, and other marine life are not as likely to attach to your hull. In advanced ultrasonic antifouling systems these frequencies are inaudible to humans, so your crew won’t be distracted by excess noise. An effective system will have transducers placed at strategic points around your hull and central control panels onboard to power and regulate the system. Installation of ultrasonic systems is usually straightforward. Some of these kits use epoxy to attach the transducers to the inside of the hull, requiring no “hot works” or hull penetrations.

Pros of ultrasonic antifouling

Ultrasonic antifouling systems provide significant benefits without harmful chemicals. These systems work by emitting ultrasonic sound waves that prevent organisms such as algae and barnacles from attaching to the hull, thereby reducing the need for biocides and ensuring compliance with environmental regulations. You don’t have to worry whether your ships will comply with various chemical regulations, and you can showcase your commitment to protecting marine environments The constant protection offered by ultrasonic systems means they are effective even when the vessel is stationary, preventing fouling accumulation during periods of inactivity. These systems are also recognized for their low maintenance requirements. Unlike traditional antifouling methods that require frequent reapplication or renewal, ultrasonic systems need minimal maintenance, which can result in long-term cost savings in terms of both labor and materials

Ready to see how much you can save with DragGone™? Try the Fuel and Emission Impact calculator!

Potential cons of ultrasonic antifouling

Older ultrasonic antifouling technologies that rely on single frequencies won’t effectively repel as wide of a range of biofouling species as modern multi-frequency systems. Choosing a traditional ultrasonic antifouling system often necessitates the installation of multiple transducers along various sections of a vessel’s hull to ensure comprehensive coverage. This can quickly become costly. In contrast, modern ultrasonic antifouling systems, such as those incorporating guided wave technology, are far more efficient. Guided wave technology leads to less energy loss and will significantly extend the area each transducer can protect. Consequently, modern systems can achieve the same hull coverage with up to 60% fewer transducers than traditional setups.

There is also a relatively high setup cost for ultrasonic antifouling systems, but you recoup these costs typically in less than one year. If you’re considering ultrasonic antifouling for internal pipework in addition to hull applications, it’s important to note the current limitations of single transducer technology. Presently, these systems are not ideally suited for treating internal pipework due to the limitations of the existing technology. Until more advanced ultrasonic systems are specifically developed to target pipework effectively, your most reliable option for preventing marine growth in these areas is to use copper-based systems. These traditional methods continue to provide dependable results for internal marine pipework protection.

Manual cleaning during dry docking

You may choose to give your vessels a thorough cleaning regularly to remove biofouling. This technique involves moving the ship onto a dry dock, cleaning it well, and repairing any damage to the hull.

Pros of manual cleaning during dry docking

Dry docking is standard in ship maintenance. Dry docking regulations for commercial vessels are primarily governed by the International Convention for the Safety of Life at Sea (SOLAS), which mandates that cargo ships must be dry docked at least twice within a five-year interval. Also, there should be no more than three years between consecutive dry dockings, with a minimum two-year interval to ensure thorough inspections and maintenance. The process allows you to thoroughly inspect your vessel for damage and fix anything impacting its performance.

Potential cons of manual cleaning during dry docking

Barnacles and other marine organisms proliferate. If you aren’t using a reliable proactive antifouling technique, you must clean your ship often. Barnacles can grow by as much as 10% in three months. Unless you also clean your hulls in the water, you must dry-dock them more often to remove biofouling, which is expensive and time-consuming.

In-water cleaning

In-water cleaning of vessels can effectively manage biofouling, crucial for maintaining the vessel’s efficiency and reducing the spread of invasive species. This method involves divers or robotic systems that clean the vessel’s hull underwater without needing to dry dock the ship. While it offers a more immediate and less disruptive option, it’s essential to consider that this process can dislodge organisms and contaminants, which may impact the marine environment. To mitigate this, technology that captures these dislodged materials is recommended. Transport Canada, for instance, has guidelines that favor proactive cleaning to manage “microfouling” before it escalates to more visible “macrofouling,” which poses a higher risk of spreading invasive species

Pros of in-water cleaning

Regular in-water maintenance allows ships to continue operating without the significant downtime associated with dry docking, which can be both time-consuming and expensive. This method also tends to be cheaper because it avoids the heavy lifting and yard fees associated with dry docking. This method offers more flexibility as it can be performed at anchor or while the vessel is docked, without needing to schedule a dry dock. It’s particularly advantageous for vessels that operate continuously and cannot afford long periods out of service.

Potential cons of in-water cleaning

Although in-water cleaning is a relatively cost-effective solution for managing biofouling, it can have negative environmental impacts. The process may dislodge and release non-native species and other contaminants into the water, potentially harming the local marine ecosystem. Manually cleaning a large vessel underwater is not only labor-intensive but also poses significant safety risks to divers. The process requires skilled personnel who can handle the physical demands and hazards of underwater work, including dealing with complex equipment and potentially dangerous marine growth.

The best antifouling methods for commercial vessels

Manual cleaning is labor-intensive and potentially dangerous activity. Your best bet for antifouling large ships and commercial fleets is to combine novel antifouling coatings with proactive antifouling systems like ultrasonic devices, such as Cathelco’s DragGone™.

Our ultrasonic system is an advanced biofouling management system explicitly designed for vessel hulls. This system emits multiple frequencies that propagate through the hull structure effectively repelling biofouling organisms from your hull with 60% fewer transducers required compared to traditional ultrasonic antifouling systems. As your ships travel the globe, they move through seas at different temperatures and salinity levels.

Relying on an ultrasonic device with a single frequency is not adequate for the range of fouling you may see on your hulls. Our system uses guided waves to reduce energy loss, allowing complete hull protection. Since the frequencies cover a larger surface area of the hull, you don’t need as many transducers. With the right antifouling system, you can get the most out of your ships for a long time.