How to create a Biofouling Management Plan

Biofouling can reduce vessel efficiency, increase fuel consumption, and lead to costly maintenance, making a biofouling management plan essential for ship owners and operators. By following IMO guidelines and implementing proactive antifouling measures, vessels can minimize biofouling risks, improve performance, and stay compliant with regulations. This guide covers how to create a biofouling management plan, from selecting antifouling solutions to ongoing monitoring and maintenance.

The problem with biofouling

Biofouling is the natural accumulation of aquatic organisms like algae, mollusks, and barnacles on submerged surfaces. This buildup comes with several challenges for marine professionals, especially when it’s formed on your vessel’s hulls, internal pipes, sea chests, or sea strainers.

Biofouling can compromise operational efficiency and increase fuel consumption, producing more greenhouse gas (GHG) emissions. One study found that microfouling on a ship’s hull can decrease vessel efficiency by 10% to 16%. Meanwhile, macrofouling can lower the vessel’s cruising speed by up to 86%.

Considering these challenges, the International Maritime Organization (IMO) has developed guidelines for vessel owners and operators, requiring them to create a comprehensive biofouling management plan (BMP).

A biofouling management plan includes regular vessel inspections, choosing the best antifouling solution, and continuous monitoring. When done right, a BMP will benefit you in the short and long term.

Introduction to biofouling and its impact

Biofouling is the buildup of various marine organisms on submerged surfaces. It could be your ship’s hull, sea chests, or sea strainers. However, these microorganisms will also reach enclosed areas of vessels, like seawater cooling pipes.

downloaded and used by 1000+ operators

Get Cathelco’s Biofouling Management Plan and Record Book

Biofouling on a ship’s hull increases hydrodynamic drag, leading to higher fuel consumption. This, ultimately, results in higher operational costs and environmental footprint. Your vessel requires more energy to propel through the water as the microorganism buildup increases hull roughness.

Of course, more fuel consumption will directly translate into more GHG emissions.

IMO’s research found that biofouling accounts for roughly 3% of the global maritime sector’s GHG emissions. In fact, even 0.5 mm of a slime layer on half of a vessel’s hull can raise greenhouse gas emissions by 20-25%.

Biofouling can be even more disastrous for your ship itself. It can potentially damage the vessel’s cooling and ballast systems, which are extremely costly to repair.

Regulatory overview

The IMO regulates biofouling on vessels and its impact on the environment. It has issued comprehensive guidelines to help vessel owners and operators tackle biofouling and minimize its carbon footprint.

According to the latest IMO guidelines, every marine professional owning or operating a vessel should:

- install an effective anti-fouling system (type-approved)

- implement a biofouling management plan (BMP), including strategies for monitoring and managing biofouling risks

- maintain a biofouling record book to document compliance with regulations

- regularly inspect and maintain contingency action plans

Besides these global guidelines, some regions or states also have regulations you must follow to operate in their waters. For example, California’s biofouling management plan provisions requires vessel owners or operators to have a plan for managing biofouling and keeping the ship ready for inspection.

Why a biofouling management plan is essential

Every vessel owner needs a biofouling management plan to operate in compliance with international and national laws. It is even more important for the longevity of your vessel itself.

Protects ship efficiency

The most prominent impact of biofouling is on the ship’s efficiency. When marine organisms attach to a vessel’s hull, they create rough surfaces that hinder water flow. This makes it challenging for a ship to move through the water, propelling it to consume more fuel.

An effective BMP helps ship owners prevent these challenges by outlining strategies for controlling biofouling. The plan will include regular inspections and maintenance schedules. This will ensure a vessel’s efficient performance and fuel consumption.

Regulatory compliance

Biofouling is a global and regional concern. No wonder strict regulations require vessels to maintain proper biofouling management and avoid the spread of invasive species. Globally, all vessel owners or operators should comply with the IMO’s established guidelines, specifically when entering areas with sensitive marine ecosystems.

A well-structured BMP comes in handy in this regard. It will align vessels with regulatory requirements to avoid fines and operational delays.

In fact, a BMP can also allow access to ports with strict biofouling controls.

Environmental protection

Biofouling isn’t only a headache for ship operators, but it also risks the life of marine ecosystems.

Vessels with biofouling can transport nonindigenous species from one place to another. When these species try to outcompete native species for resources, it can significantly disrupt local marine populations. This can lead to biodiversity loss and ecological imbalances.

A BMP aligns ship owners with their vessel’s cleaning and maintenance schedules. This prevents harmful organisms from spreading, preserving marine biodiversity and the health of ocean ecosystems.

Key components of a biofouling management plan

A biofouling management plan must include all the necessary components to be effective. The critical ones include:

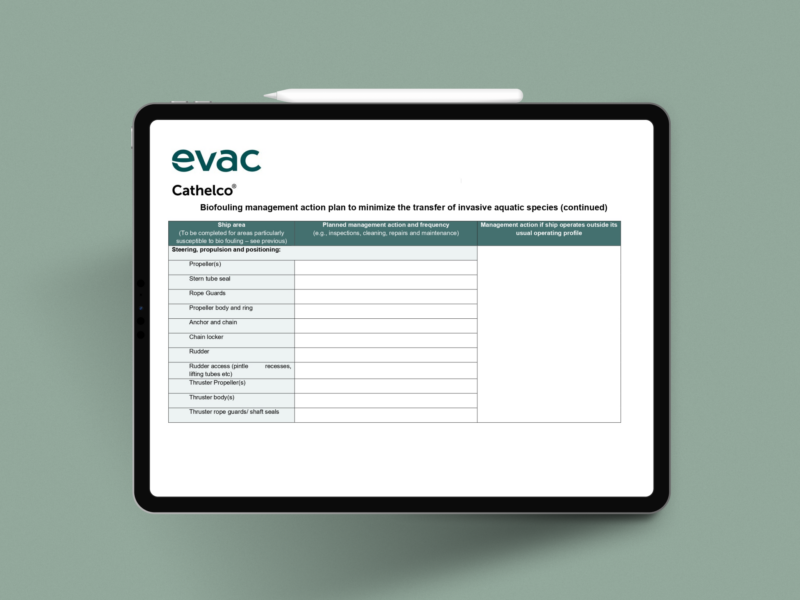

Assessing areas of a ship susceptible to biofouling

Your ship is vulnerable to biofouling in certain areas where marine organisms can quickly accumulate. These include but are not limited to the following:

- Hulls: the underwater part of a ship’s hull remains constantly submerged, making it the most susceptible to biofouling

- Sea chests: these compartments on the ship allow seawater to reach its cooling systems, which also makes way for microorganisms to enter and accumulate

- Intake gratings: these gratings cover water intake openings. Biofouling in this area can clog water flow and affect system efficiency

- Propellers: the propeller blades can easily accumulate marine growth, compromising the vessel’s efficiency in water

- Cooling systems: pipes and heat exchangers within cooling systems are also susceptible to biofouling

Selecting the right antifouling systems

You should assess different types of antifouling systems to choose the one that fits your ship’s particular needs. The four common ones include:

Copper-ion-based systems

These are traditional and proven antifouling methods that deter microorganisms by releasing copper ions into the water. The most common ones include:

- Marine growth prevention systems (MGPSs): designed to prevent biofouling from seawater piping or cooling lines inside vessels, Cathelco’s MGPS specifically increases the lifespan of the pipes, reducing maintenance and pipe replacement costs in the long run

- Impressed current cathodic protection systems (ICCPs): Cathelco’s ICCP protects the ship’s hull from corrosion by generating a current output that suppresses the electrochemical activity of the microorganisms

While copper ions have potent biocidal properties, Cathelco’s systems keep the copper ion doses at around 2-24 ppb (parts per billion). This is lower than the World Health Organization’s set limit for copper in drinking water, which is 2,000 ppb (2mg/L). This eco-friendly approach keeps barnacles at bay while preserving the environment.

Additionally, Cathelco’s systems comply with Article 95 of the EU Biocides Regulations and are listed as an authorized supplier.

Ultrasonic antifouling

Ultrasonic antifouling is an eco-friendly supplement to copper-ion-based systems as it doesn’t use harmful chemicals. This advanced method emits high-frequency sound waves to prevent microorganisms from attaching to the ship’s hull.

One such example is Cathelco’s Ultrasonic Antifouling USP DragGone™ system. Its non-biocidal solution utilizes acoustic cavitation to disrupt microorganisms and prevent them from building up on the vessel.

Chemical coatings

These coatings create a barrier that kills or repels marine organisms when they come in contact. One biocidal antifouling option is eroding antifouling. It releases chemicals when water movement triggers erosion over the hull. Some ship owners also opt for hard film antifouling, which leverages the contact leaching phenomenon in which biocides are released after contact with seawater.

Foul-release coatings

Foul-release coatings make the hull surface slippery enough that microorganisms cannot adhere to the ship. Unlike chemical coatings, they don’t kill the fouling organisms but prevent them from establishing a foothold on the vessel.

Inspection and maintenance procedures

A successful biofouling management plan also includes regular inspection and maintenance.

All types of vessels need in-water inspections at regular intervals, typically every 3 to 6 months. This helps assess biofouling levels on any vulnerable part of your ship. Make sure to note down the findings of your inspection to develop cleaning procedures and schedules efficiently.

Based on the inspection results, vessel cleaning should be performed as needed. If the biofouling has just started, minimal manual scraping may be enough to get rid of the microorganism layer. However, if there is visible buildup, use specialized tools specifically designed for underwater vessel cleaning.

Always be proactive with your cleaning schedules. Prevention is better than cure, and that certainly applies to biofouling.

Developing a biofouling action plan: Step-by-step guide to implementing a BMP

It’s time for practical groundwork. Here are three easy steps to developing and implementing a biofouling management plan:

Step 1: Initial inspection

Conduct an initial inspection of the most vulnerable areas for biofouling. Inspect the most visible areas of the ship—such as the hull and the sea chest—and then move to other parts, like intake gratings, propellers, and cooling systems.

Make sure you’re carefully observing each of these areas, including parts that are hard to reach. These are often the most favorable spaces for microorganisms to sit in and spread to other parts over time.

Document your findings in a maintenance log to track the extent of biofouling over a specific period. You should also note any cleanliness measures you take to assess their success.

Step 2: Choosing antifouling solutions

Select the appropriate antifouling systems based on your vessel’s type and operational region.

Vessel type considerations

Almost all vessels are prone to developing biofouling, but their cleaning needs vary.

For example, commercial shipping vessels that operate mainly in marine environments require robust antifouling solutions to deter microorganisms for extended periods. Owners can opt for foul-release coatings and antifouling paints, which work great with an impressed current cathodic protection (ICCP) system, such as Cathelco’s ICCP, for hull corrosion prevention.

Operators may choose soft antifouling paints if a ship has a low speed. Harder paints are recommended for vessels operating at higher speeds, as well as those that spend a lot of time in ports. These operate in shallow waters, where nutrient-rich environments make biofouling more common.

Military and patrol vessels can encounter unforeseen circumstances, so they require strong biofouling protection.

Operational region considerations

Operational region also matters. Tropical regions have nutrient-rich water due to warmer temperatures. If you’re operating in these regions, you should opt for copper-based treatments or advanced foul-release coatings to tackle biofouling.

Meanwhile, cold water regions have less nutrient-rich water, so biofouling risks are relatively lower. Vessels operating here can use hard antifouling paints but should avoid them in freshwater environments, which usually have various fouling microorganisms. Instead, biocide-free options are recommended.

You should also account for sensitive marine areas, which have strict environmental regulations for antifouling solutions. Eco-friendly options like Cathelco’s ultrasonic systems or biocide-free coatings are ideal for vessels operating in these waters.

Step 3: Continuous monitoring

Monitor the effectiveness of your antifouling solutions through a continuous monitoring system. This will allow you to assess performance and identify areas for improvement.

Cathelco’s control panels and data logging features can be very helpful, giving you instant access to critical performance data while recording your operational history, maintenance records, and performance trends.

The importance of biofouling record keeping

A biofouling record book helps ship owners maintain detailed records of inspections, cleanings, and antifouling applications. This streamlines compliance processes, as you can quickly provide documentation to authorities during inspections.

Failure to maintain the biofouling record book can lead to fines, penalties, or even denial of entry into ports. Always double-check that you’re including these details in your record book:

- ship’s operating profile, including its typical routes and operational conditions

- areas susceptible to biofouling

- maintenance logs, including cleaning dates and methods used

- antifouling systems applied to the vessel, including installation dates and maintenance details

- issues encountered related to biofouling

Besides preventing operational delays, a biofouling record book can also help you develop an effective biofouling management plan.

Long-term benefits of biofouling management

Biofouling management reaps both immediate and long-term benefits.

The first is cost savings. When your vessel isn’t restricted by biofouling, it propels more easily through water, consuming less fuel. This results in lower operational and maintenance costs, saving potentially thousands of dollars.

Biofouling management also contributes to environmental protection. By maintaining a clean, microorganism-free hull surface, you minimize the need for chemical-based antifouling solutions. Your vessel also releases lower GHG emissions.

A biofouling management plan also keeps you compliant with IMO guidelines, helping you avoid penalties and operational delays.

Implement your biofouling management plan today

Whether you’re a ship owner or operator, a biofouling management plan is essential when operating your vessel in water. It benefits your ship, operations, and the marine ecosystem.

Consult experts on antifouling systems to ensure you meet all international or regional requirements, or to learn how to create an effective biofouling management plan.