Everything you need to know about ultrasonic antifouling: The future of eco-friendly biofouling control

For the maritime industry, one of the major challenges when dealing with biofouling is to ensure sustainability. It’s difficult to get rid of the microorganism buildup on a vessel’s surface without using a biocide. While effective against biofouling, traditional biocidal solutions consist of toxic chemicals that are damaging to aquatic life.

In fact, the international maritime organization (IMO) also restricts vessel owners from using harmful antifouling solutions. That’s when modern solutions like ultrasonic antifouling systems emerge as the best alternatives.

This eco-friendly approach utilizes ultrasonic sound waves to prevent and remove biofouling from the ship’s submerged areas. It is non-toxic, allowing vessel owners to optimize fuel consumption and performance without compromising the environment. Additionally, optimal fuel consumption directly translates to less greenhouse gas (ghg) and co2 emissions.

What is ultrasonic antifouling?

Ultrasonic antifouling is an eco-friendly, non-biocidal approach to preventing and managing marine growth (or biofouling) on a ship’s hulls.

It works on “acoustic cavitation,” in which high-frequency sound waves produce microscopic bubbles in the water. When these bubbles burst, they rupture the cells of biofouling organisms through localized pressure changes. This prevents them from attaching to the vessel’s hulls at an early stage.

Unlike traditional methods, ultrasonic antifouling works as a proactive approach instead of being reactive. It’s also non-toxic, allowing ship owners to protect their vessels while reducing their environmental footprint.

TACTICAL, PRACTICAL, PROVEN ADVICE

Download the ultimate buyer’s guide to ultrasonic antifouling systems

Understanding marine biofouling and its impact on ship performance

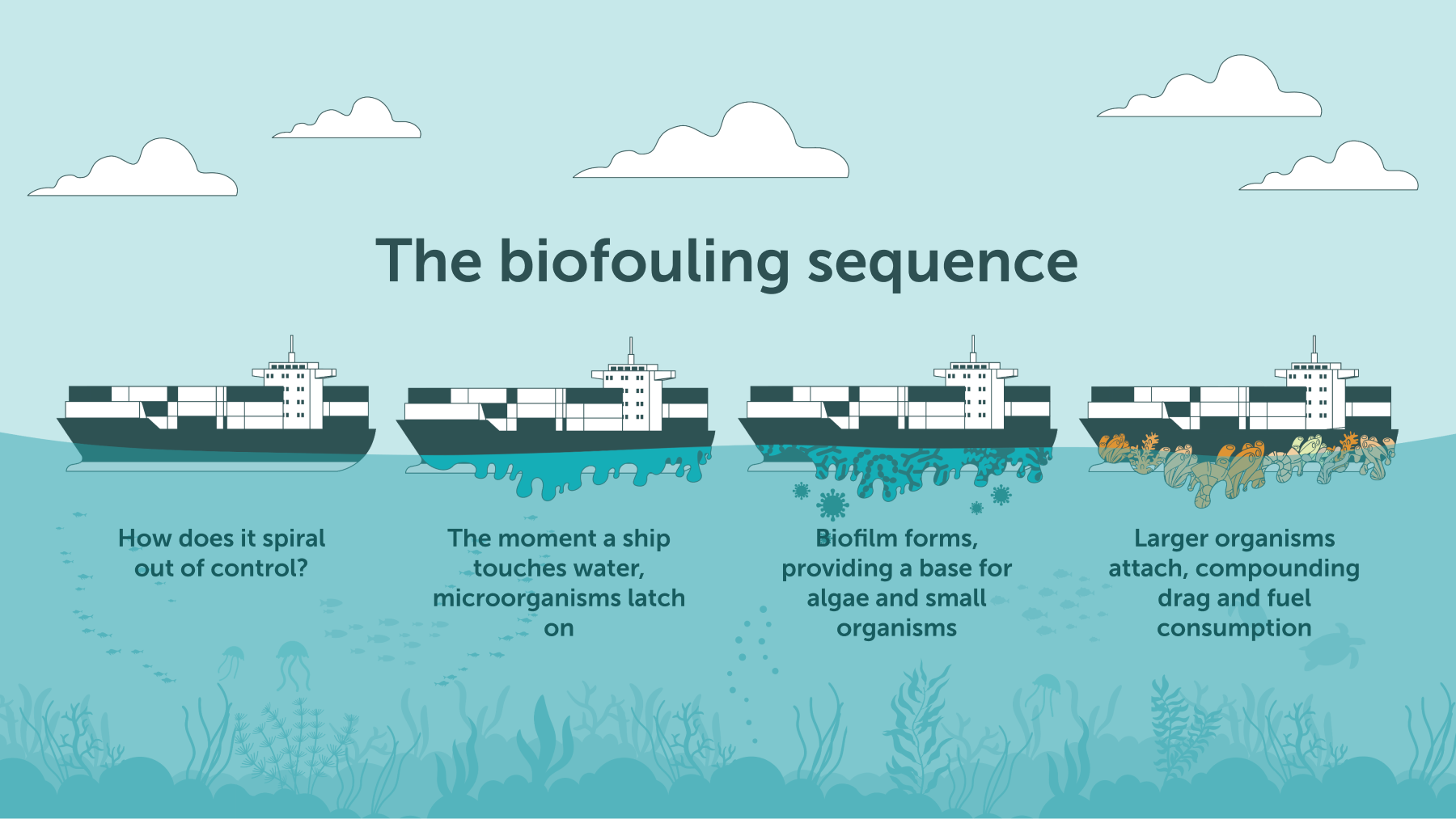

Marine biofouling is the natural buildup of aquatic microorganisms on specific submerged parts of vessels. Areas like hulls, propellers, sea chest, and even cooling systems provide easy access to barnacles, algae, and mussels to enter and grow. This undesirable accumulation comes with significant economic and environmental consequences.

First, biofouling increases drag on the hull, making it challenging for the vessel to propel through water. As a result, it consumes more fuel, producing greenhouse gasses (GHG) — a big environmental toxicant.

On estimate, biofouling can reduce a vessel’s speed by up to 10% and fuel efficiency by 40%. An IMO research also found biofouling to be causing 20-25% more GHG emissions, which was only for a 0.5 mm layer of slime covering only half of the hull. Imagine if this buildup was on the entire hull!

Second, biofouling significantly adds up to higher operational costs for ship owners. A Science Magazine report found the us shipping industry spends more than $36 billion annually in added fuel costs because of biofouling.

Third, biofouling-affected hulls can contribute to the spread of invasive species across marine ecosystems.

Implementing antifouling methods is a viable solution to tackle all these challenges.

Development of ultrasonic antifouling technology

Ultrasonic antifouling isn’t a novel concept. The technology was first used in military devices in the early 20th century. In the 1950s, the US navy conducted a few submarine tests and found ultrasonic technology’s efficacy in reducing fouling around sonar transducers. This was only the beginning of ultrasonic applications in marine environments.

In the 1980s, M.E.S. S.r.l. Started researching and developing the first-ever ultrasonic fouling systems for naval use cases. By the late 1990s, tests in commercial systems first started in the cruise industry, paving the way for ultrasonic systems in the 2000s.

Today we have fully digital ultrasonic antifouling systems with efficient control and diagnostic features. They leverage advanced transducers that produce ultrasonic waves at varying frequencies.

The control panels of ultrasonic antifouling systems have also evolved. You can achieve precise frequency and power tuning without impacting marine life. These innovations have made this technology a preferred choice for ship owners who believe in preserving marine health.

Effectiveness of ultrasonic antifouling

Over the years, several studies have proven the effectiveness of ultrasonic antifouling technology in reducing marine growth and improving ship efficiency.

For instance, one Brunel university study experimented with a two-square-meter plate equipped with ultrasonic transducers. The researchers submerged it in seawater for 35 days to test the technology’s efficacy. To their surprise, the resulting photographs showed a remarkable reduction in biofouling on the plates.

Ultrasonic technology works wonders on different types of marine growth. This includes even the hard buildup — caused by mussels and barnacles — and fouling slime — consisting of algae and similar microorganisms. You can also find vessel-specific ultrasonic antifouling systems for different types of ships.

Installation and maintenance of ultrasonic antifouling systems

Ultrasonic antifouling systems have easy installation, but you may need professional help for large vessels. Here is how Cathelco’s recently announced ultrasonic antifouling system, USP DragGone™, is installed:

- Site assessment and preparation. First, professionals evaluate the hull or any other underwater surface and prepare it to bare metal.

- Transducer positioning and mounting. Then, they measure the hull’s thickness and position the transducer on it. Epoxy is then applied to the mount transducer and a mounting plate is attached to the prepared hull surface for the transducer.

- Junction box and control panel installation. Now, professionals install the junction box and control panel, and connect transducer cables to the junction box. The grounding connections are then secured.

- Cable connections. Finally, they connect cabling from the junction box to the control panel, and the power supply to the control panel and the transducers.

- Frequency testing. Once experts run some frequency tests to verify system operations, the installation is completed.

At Cathelco, we also train the vessel crew to operate, monitor, and maintain the ultrasonic antifouling systems. These systems require periodic inspections to detect signs of wear and tear or debris and marine growth.

Ultrasonic antifouling vs. Traditional solutions

Here is a detailed comparison of ultrasonic antifouling and traditional solutions:

| Features | Ultrasonic antifouling technology | Traditional solutions |

| Environmental impact | • non-toxic; next generation systems pose no harm to marine life • reduces bio-waste and microplastic risks | • release potential microplastic and biocide • generate bio-waste that contributes to pollution • produce volatile organic compounds (VOC) emissions during application that can harm aquatic ecosystems |

| Cost | • lowers long-term costs as its 24/7 protection eliminates frequent cleaning • requires 60% fewer transducers | • higher ongoing costs due to regular maintenance, repainting, and disposal of hazardous materials |

| Operational efficiency | • reduces fuel consumption by up to 13% by maintaining a clean hull • improves speed and maneuverability | • require frequent reapplications that may fail to keep the hulls clean for a longer period, resulting in higher fuel consumption and reduced operational efficiency. |

| Installation | • easy installation without the need for dry docking • can be installed at any time | • often require dry docking for application, which can disrupt operations |

| Maintenance needs | • minimal or no maintenance required | • frequent maintenance needed to reapply coatings and scrub hulls |

| Effectiveness against growth | • works on both hard growth and fouling slime through acoustic cavitation | • effective but often limited in scope |

Ready to see how much you can save with DragGone™? Try the Fuel and Emission Impact calculator!

Risks and considerations

Ultrasonic antifouling systems have undergone several rigorous evaluations to ensure they’re safe for marine life. One such example is Cathelco’s USP DragGone, which the DHI maritime technology evaluation facility has assessed for its impact on various marine mammal groups, including:

- Low-frequency cetaceans (e.g., whales)

- Mid-frequency cetaceans (e.g., certain dolphins and small to mid-sized toothed whales)

- High-frequency cetaceans (e.g., harbor porpoises)

The test utilized advanced computer modeling to analyze potential risks. The results showed that ultrasonic waves don’t interfere with the sonar navigation of any of these species, proving its environmentally friendly approach toward marine ecosystems.

If you’re not achieving your desired cleaning results from ultrasonic antifouling, you can try using it in conjunction with other eco-friendly methods. At Cathelco, we offer impressed current cathodic protection (ICCP) and marine growth prevention systems (MGPS) — both of which give impressive results against hull biofouling.

Recent advancements in technology

Ultrasonic antifouling technology has come a long way since its inception. Some key advancements include:

- Guided wave technology. This next-generation solution allows for hull protection over 2000m² vs. 50m² — about 40x more effective than standard systems. It also results in 60% fewer transducer needs during installation.

- Heterodyning technology. This principle allows ultrasonic systems to operate across a broader range of frequencies, treating a wider variety of biofouling organisms. Because fouling organisms react to different frequencies, systems that operate with single frequencies only treat that subset of fouling organisms sensitive to the set frequency range. With multiple frequencies, a wider range of fouling organisms are treated, ensuring more comprehensive biofouling prevention.

- Energy-efficient transducers. Modern ultrasonic systems utilize low-power transducers that consume as low as 3.6 watts per transducer of energy. It not only lowers operational costs but also aligns with your sustainability goals.

These advancements work together to significantly cut down on maintenance, cleaning costs, and overall operational expenses.

Compliance with IMO biofouling guidelines

The IMO 2023 guidelines aim to reduce the spread of invasive species across the marine ecosystem. They also condemn using antifouling biocides, requiring ship owners to opt for eco-friendly options. By checking all of these boxes, ultrasonic antifouling systems help marine professionals comply with IMO biofouling guidelines.

These solutions are non-toxic for marine organisms, so they effectively eliminate biofouling species without disrupting others. Ultrasonic technology also reduces the risk of chemical pollution in oceans and contributes to healthier marine ecosystems.

There are several economic impacts of ultrasonic antifouling systems as well. They keep the hull clean 24/7, allowing vessels to easily propel through water and consume less fuel. This results in up to 13% of fuel savings, meaning less operational costs over time.

Advantages of ultrasonic antifouling

As a reminder, the benefits of ultrasonic antifouling systems include:

Regulatory compliance. Ultrasonic antifouling aligns with IMO’s environmental and economical regulations, allowing you to meet compliance standards.

Environmental sustainability. These solutions are completely non-toxic, posing no harm to marine life.

Fuel efficiency. By maintaining a clean hull, they can lead to fuel savings of up to 13% by reducing the drag.

Reduced maintenance costs. These solutions include no need for haul-outs, scrubbing, and repainting, leading to lower operational and maintenance costs.

Proactive hull protection. Unlike traditional methods that work after biofouling has formed, ultrasonic antifouling prevents marine organisms from attaching to the hull in the first place.

Easy installation. These systems don’t require dry-docking or through-hull penetrations, so installing them is pretty easy.

Disadvantages of ultrasonic antifouling

With good, there are some bad. The same is the case with ultrasonic antifouling. However, its advantages easily outweigh its disadvantages, which include:

Waterline protection. Older systems may struggle to prevent fouling growth at the waterline. However, they work fine in conjunction with another antifouling method.

Higher upfront cost. You may have to pay more for ultrasonic antifouling systems initially, but it helps you save significantly in the long run.

Material incompatibility. Some ultrasonic antifouling may be less effective on certain hull materials or internal structures.

Evaluating ultrasonic antifouling for vessels

When it comes to biofouling, ultrasonic antifouling is truly a savior for the environment as well as the vessel owners. It enables the vessels to consume less fuel, operate effectively, and produce less carbon footprint on the environment.

While these systems may have a few limitations, their advantages overshadow their downsides.

Consult experts today to learn how an ultrasonic antifouling system can help you achieve your performance and fuel efficiency goals.

Frequently asked questions about ultrasonic antifouling

How does ultrasonic antifouling work?

Ultrasonic antifouling works on acoustic cavitation. The system produces high-frequency sound waves that generate microscopic bubbles, which burst and create localized pressure that interacts with microorganisms. This ruptures their cells and prevents them from attaching to the hull’s surface.

Does ultrasonic antifouling require dry-docking for installation?

Most ultrasonic antifouling systems do not require dry-docking, making installation convenient and less disruptive to operations. Transducers are typically mounted on the hull’s interior with no hull penetrations required, enabling easier setup and integration.

Why is multi-frequency ultrasonic technology better than single-frequency?

Multi-frequency technology addresses a broader spectrum of biofouling organisms, as each type may respond to different frequencies. This approach ensures comprehensive biofouling management by adapting to various organism sensitivities, unlike single-frequency systems, which may miss certain biofouling types.

Can ultrasonic antifouling be used with other biofouling prevention methods?

Ultrasonic systems are often compatible with complementary systems like cathodic protection and other marine growth prevention solutions. This combination can enhance overall biofouling management, especially in high-fouling environments or on vessel types with unique fouling challenges.

Is ultrasonic antifouling safe for marine ecosystems?

Yes, ultrasonic antifouling is a non-toxic approach, avoiding harmful chemicals. Unlike traditional antifouling paints that release biocides, ultrasonic systems rely on sound waves to prevent organism attachment, aligning with IMO environmental standards to protect marine biodiversity.

What features make an ultrasonic antifouling system more effective?

An effective ultrasonic antifouling system uses technologies like multi-frequency emissions, which treat a wider range of biofouling organisms. Additionally, advanced systems employ guided wave technology, ensuring ultrasonic waves cover larger areas, significantly reducing the number of transducers needed for full hull protection.

Contact the Ultrasonic Antifouling sales team

Our expert team is here to guide you through our Ultrasonic Antifouling Solutions tailored to your specific needs.