Why every vessel needs ultrasonic antifouling

Ultrasonic antifouling offers a non-toxic, proactive solution to hull biofouling, enhancing fuel efficiency, reducing emissions, and ensuring compliance more effectively than traditional methods.

Biofouling occurs when aquatic organisms — including algae, barnacles, and mussels — attach to underwater surfaces. This buildup compromises vessel performance by increasing drag and diminishing fuel efficiency. Your vessels will consume more fuel and generate higher greenhouse emissions. Unrestricted biofouling also raises operational costs and increases your environmental footprint. You can unwittingly become noncompliant with regulations to reduce these effects, leading to potential fines and other penalties.

Ultrasonic antifouling is a marine growth prevention system that provides a non-biocidal approach to managing hull biofouling. It prevents marine organisms from growing on submerged surfaces of your vessel by disturbing the accumulation of fouling organisms at the earliest stages. Ultrasonic antifouling is not a new technology, but recent developments in this technology have increased the effectiveness of its capabilities.

Understanding biofouling

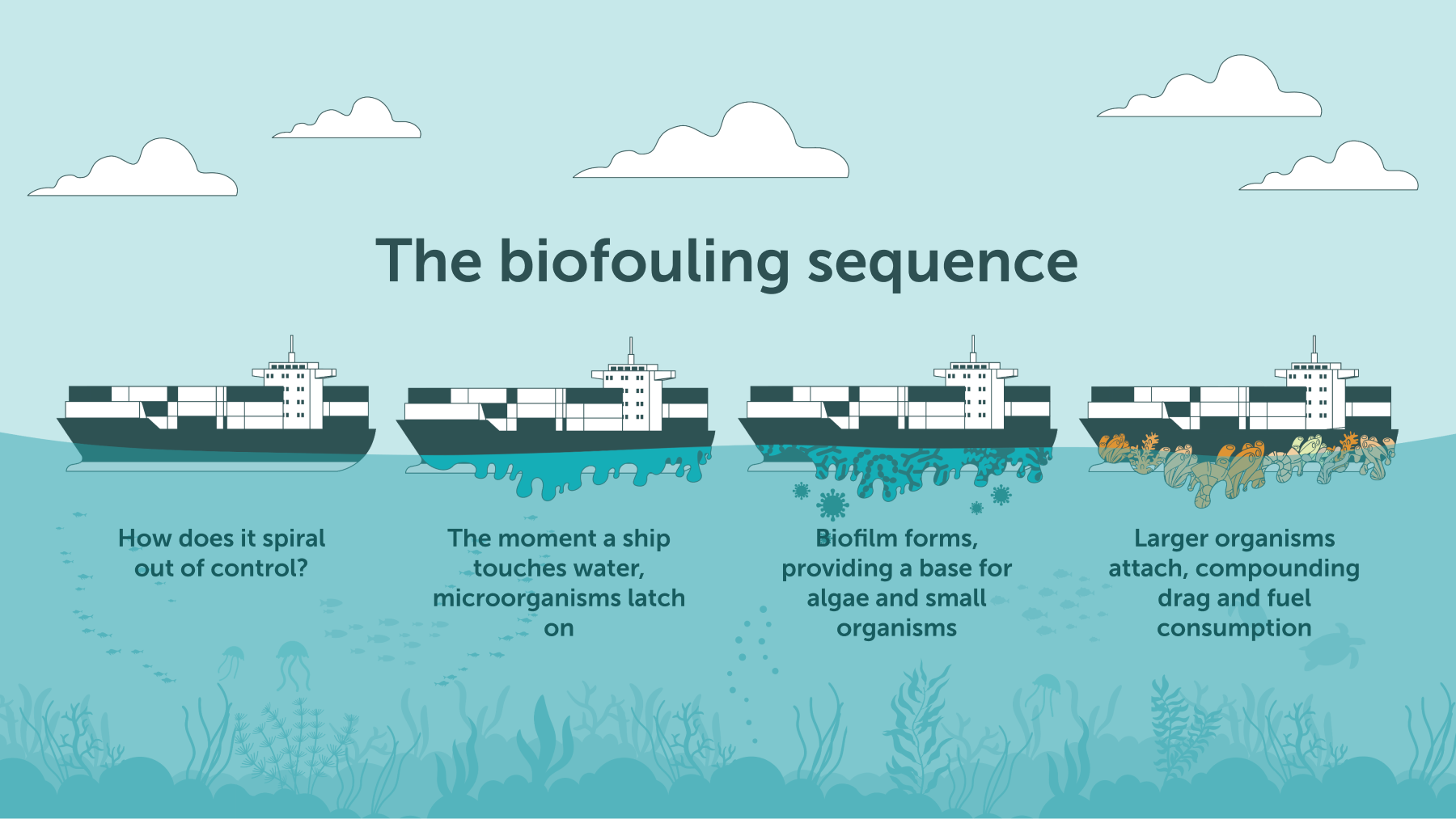

Biofouling is the buildup of aquatic organisms on submerged surfaces. These include the hulls of ships, underwater pipelines, and marine installations. This process starts when a thin layer of bacteria and other microorganisms create a biofilm on submerged surfaces. Larger organisms, like barnacles, mussels, seaweed, and tube worms, then attach to the biofilm. As this aquatic life grows, it forms a thriving community. Unfortunately, this community greatly interferes with the ship’s functions. Collectively, they can significantly interfere with maritime operations.

Heavily fouled hulls experience increased hydrodynamic drag, resulting in slower speeds and decreased fuel efficiency. Biofouling can decrease a vessel’s speed by up to 10% and decrease fuel efficiency by as much as 40%. Research conducted by the International Maritime Organization found that even a 0.5 mm layer of slime covering half a vessel’s hull surface can increase greenhouse gas emissions by 20-25%, so biofouling is a critical environmental issue. Biofouling also increases maintenance costs, leading to more frequent dry-docking, cleaning, and reactive antifouling to remove the buildup.

Difficulties with biofouling

Perhaps the most significant impact of biofouling on biodiversity is that it introduces and spreads invasive species. These organisms can outcompete native species for resources. Their explosive growth reduces natural diversity, changes the native ecosystems, and introduces new diseases to native species.

Biofouling also occurs on structures like docks, piers, and offshore platforms, where it creates habitats that further change local ecosystems. While these structures sometimes provide new habitat areas for native organisms, they more often benefit invasive species.

There are strict environmental regulations to reduce the harm caused by biofouling. International conventions have passed regulations to mitigate the spread of invasive aquatic species and reduce the ecological impact of biofouling. However, complying with these regulations using traditional antifouling methods, such as toxic chemical coatings or manual cleaning, is difficult and expensive. These methods are also often ineffective and environmentally damaging.

Traditional vs. ultrasonic antifouling

Traditional methods for managing biofouling mainly focus on reactive measures. These measures include applying antifouling coatings and regularly cleaning hulls.

Antifouling coatings contain biocidal products meant to deter organism attachment. Unfortunately, they can contain toxic substances that can leak into the sea, harming non-target species. Hull cleaning without biocidal products is labor-intensive and costly. It also sidelines ships while in dry dock. Dislodged biofouling can damage coatings and cause more environmental impact.

Ultrasonic antifouling is an eco-friendlier approach to biofouling management technology. It uses high-frequency sound waves to create an inhospitable environment for biofouling organism attachment.

Unlike traditional methods, ultrasonic antifouling is non-toxic. It works continuously to protect the vessel’s hull without adding harmful chemicals to the sea.

Ultrasonic antifouling is proactive, not reactive. It targets the earliest biofilm, which results in improved vessel performance and fuel efficiency, as the hull remains cleaner for longer periods. The non-toxic nature of ultrasonic antifouling also aligns with increasing environmental regulations, providing a sustainable solution to reduce the marine industry’s ecological footprint.

Benefits of ultrasonic antifouling

The most immediate benefit you’ll see from ultrasonic antifouling is fuel savings. By preventing biofouling accumulation, ultrasonic systems keep the hull’s surface smooth and free of organisms that can increase drag. A clean hull maintains optimal hydrodynamic performance, so your vessels use less fuel. Ultrasonic antifouling can improve fuel efficiency by up to 13% or more. This translates into substantial cost savings over time.

Reduced fuel consumption directly correlates with lower greenhouse gas emissions. In particular, your fleet will produce less carbon dioxide, sulfur oxides, and nitrogen oxides — all major contributors to air pollution and climate change.

Ultrasonic antifouling technology also reduces maintenance costs. Traditional hull cleaning and antifouling coatings are expensive and slow, and you often need to dry-dock your vessel for maintenance. By preventing biofouling in the first place, ultrasonic systems reduce the need for these procedures, decreasing both the frequency and cost of maintenance.

Environmental compliance and sustainability

Ultrasonic antifouling can help you achieve your environmental sustainability goals and improve compliance. It addresses the immediate challenges of biofouling management and sets a precedent for environmentally conscious practices in the industry.

As global and regional bodies tighten the reins on maritime environmental impact, they’re focusing on slowing the spread of invasive species and preventing water pollution with toxic chemicals. Ultrasonic systems offer a compliance-friendly solution by preventing biofouling without the use of harmful biocides. They adhere to the International Maritime Organization’s guidelines and regulations to prevent biofouling. This non-invasive method adheres to current regulatory standards as well as likely future restrictions on chemical treatments.

Ultrasonic methods also help preserve biodiversity by limiting the spread of non-native species. The energy efficiency gains from maintaining cleaner hulls contribute significantly to reducing greenhouse gas emissions. Put together, all this supports the maritime industry’s broader sustainability objectives.

Looking ahead, ultrasonic antifouling will likely become the benchmark for hull biofouling management, pushing the industry towards more sustainable practices. It fits in with the ongoing shift towards greener shipping technologies and eco-friendly supply chains. Ultrasonic antifouling is driving innovation and environmental stewardship in the industry.

The role of USP DragGone™ in ultrasonic antifouling

USP DragGone™ is the next-generation solution in ultrasonic antifouling technology. Its patented technology boosts ultrasonic’s effectiveness and coverage area. The GUIDED WAVE technology gives you antifouling protection over much larger distances and areas — approximately a 25m radius covering around 2,000m², which is roughly 40 times the area protected by standard ultrasonic systems. This expanded coverage simplifies installation and maintenance.

The HETERODYNING feature incorporates a broader range of ultrasonic frequencies and allows USP DragGone™ to target a wider variety of fouling organisms. This adaptability makes it a more versatile solution than other products. It’s capable of addressing the wide variety of organisms that cause biofouling. It also integrates well with your existing technology, such as copper-based marine growth prevention systems and non-biocidal antifouling coatings.

In terms of environmental compliance and sustainability, USP DragGone™ is in line with the International Maritime Organization’s ambitious targets for carbon intensity reduction and net-zero emissions. By mitigating biofouling-induced fuel consumption and GHG emissions, USP DragGone™ contributes to an estimated 48,000-ton reduction in CO2 over five years.

Furthermore, it supports fleet operators in their sustainability commitments, an increasing concern in many organizations undergoing environmental, social, and governance (ESG) audits. Many organizations now rely on the results of ESG audits to make investing decisions. Making the switch now will make your business more appealing to forward-thinking investors.

Investing in USP DragGone™ boosts ship efficiency and sustainability. It also future-proofs maritime operations. As the industry shifts towards greater environmental responsibility, USP DragGone™ gives you a strategic advantage, allowing you to confidently meet current and future market conditions.

Try DragGone™ ultrasonic antifouling today

Ultrasonic antifouling is the future of maritime efficiency and environmental stewardship. Through technologies like USP DragGone™, you can benefit your bottom line and the planet. Find out exactly how much you can save by using the DragGone™ Fuel and Emission Impact Calculator. This tool will show you how much you can expect to save in fuel and maintenance costs as well as how much of a reduction in your greenhouse gas emissions you can expect. Reach out today to learn more.