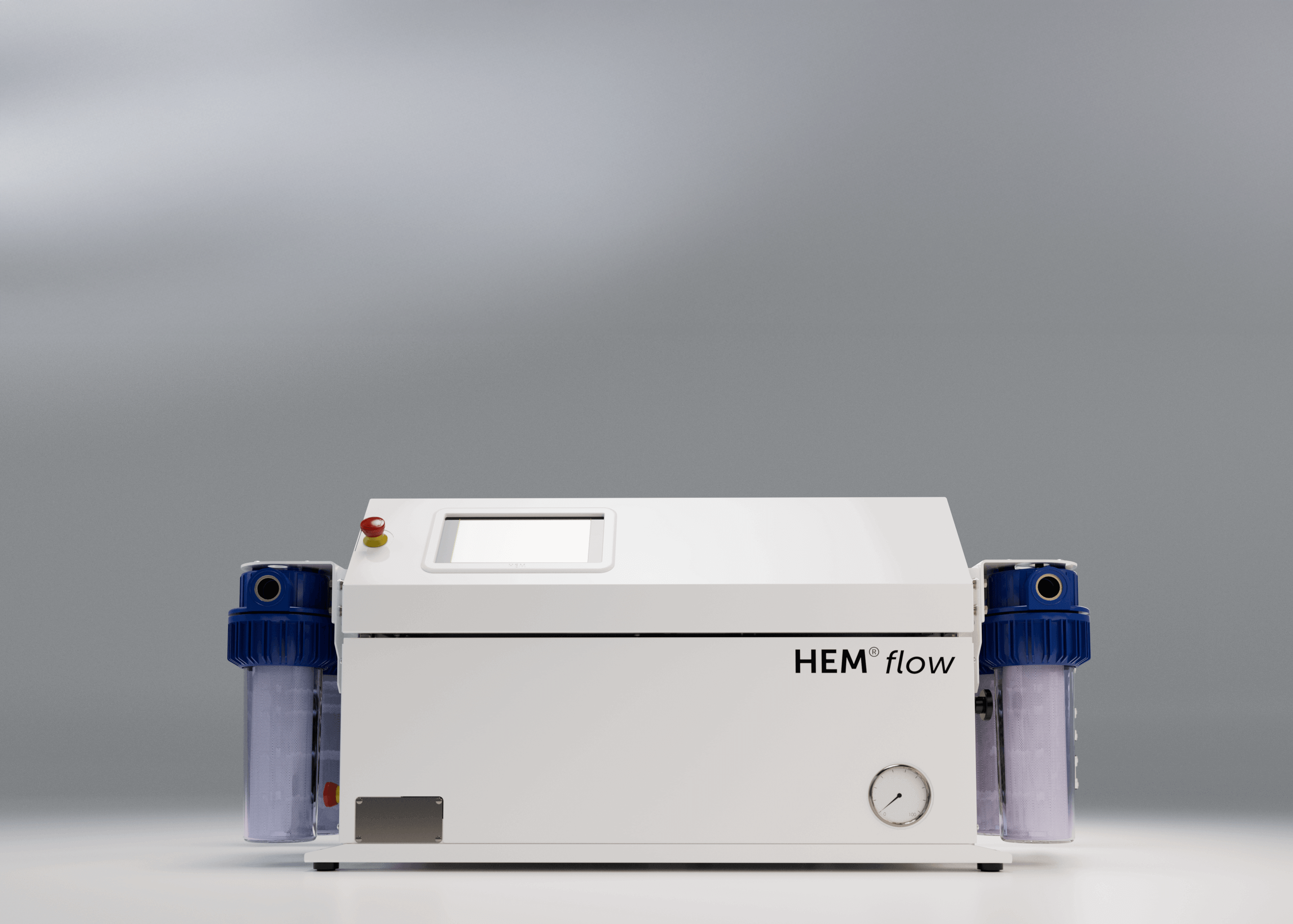

HEM performance and quality, sized and priced for 20-50 meter yachts for the first time

HEM flow is ideal for yacht projects where space and budget is limited, and reliability is critical.

It helps designers, builders and operators choose a freshwater system that fits the vessel, supports smooth operations and makes long-term ownership straightforward.

22% lighter

34% smaller

Compact and modular for an easier fit

20% quieter

Low vibration and reduced noise for safety and comfort

Simplified design results in shorter lead times and faster hand-over

Reliable performance using renowned HEM design standards

Model range

The Flow series covers typical freshwater demands for 20–50m yachts.

HEM Flow 3

Generates up to 3.7 m³ fresh water per day

HEM Flow 5

Generates up to 5.1 m³ fresh water per day

HEM Flow 6

Generates up to 6.6 m³ fresh water per day

Which model fits your project?

Multiple variations and configuration options make HEM Flow easy to spec and fit for any project.

Try the HEM Flow configurator to see which model and variation is the right one for you.

Recommended setup

Contact HEM sales

Share your details and we’ll route the configuration to our team.

Found your match?

Two product levels to match different project needs

Both Standard and Pro versions of HEM flow deliver reliable freshwater production.

The choice comes down to how much integration, control and finish your yacht project needs.

HEM Flow Standard

Best when you need:

- A dependable watermaker at a sharp price point.

- Straightforward operation with more limited automatic system process control.

- A standalone unit without full integration into the yacht’s automation system.

Key characteristics:

Carbon post-filter for potable water quality.

Basic automatic system process control with operating pressure and product water salinity.

Volt-free contacts for warnings and alarms.

Brushed 304L stainless steel frame with a functional, clean industrial look.

Choose Standard for simple, robust freshwater production at the best possible value.

HEM Flow Pro upgrade

Best when you need:

- Connection to the yacht’s automation and monitoring system (AMCS).

- More information to support planned maintenance and smooth operation.

- A higher-end coating finish that matches the overall standard of the machinery space.

Key characteristics:

Additional pre- and post-treatment options, such as sand filters for large particle pre-filtration and limestone + carbon, for taste and pH adjustment.

Advanced automatic system control with product flow rate and feed water temperature.

Maintenance alerts and performance trending visible on the HMI.

User access levels to separate crew and service functions.

Full Modbus integration plus extended volt-free contacts for AMCS.

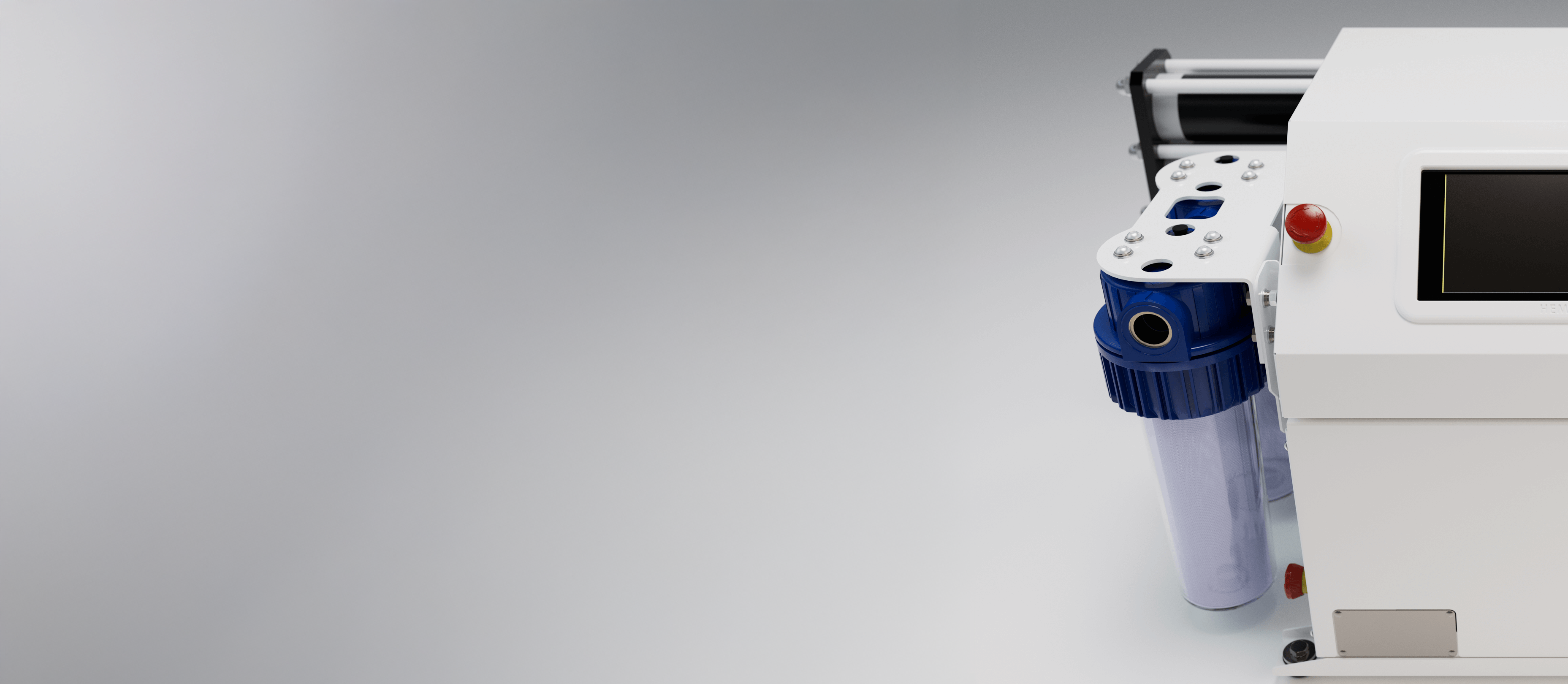

High gloss white frame (RAL 9003 as standard, other colours on request).

Choose Pro when integration, additional control and a refined finish are part of the yacht’s requirements.

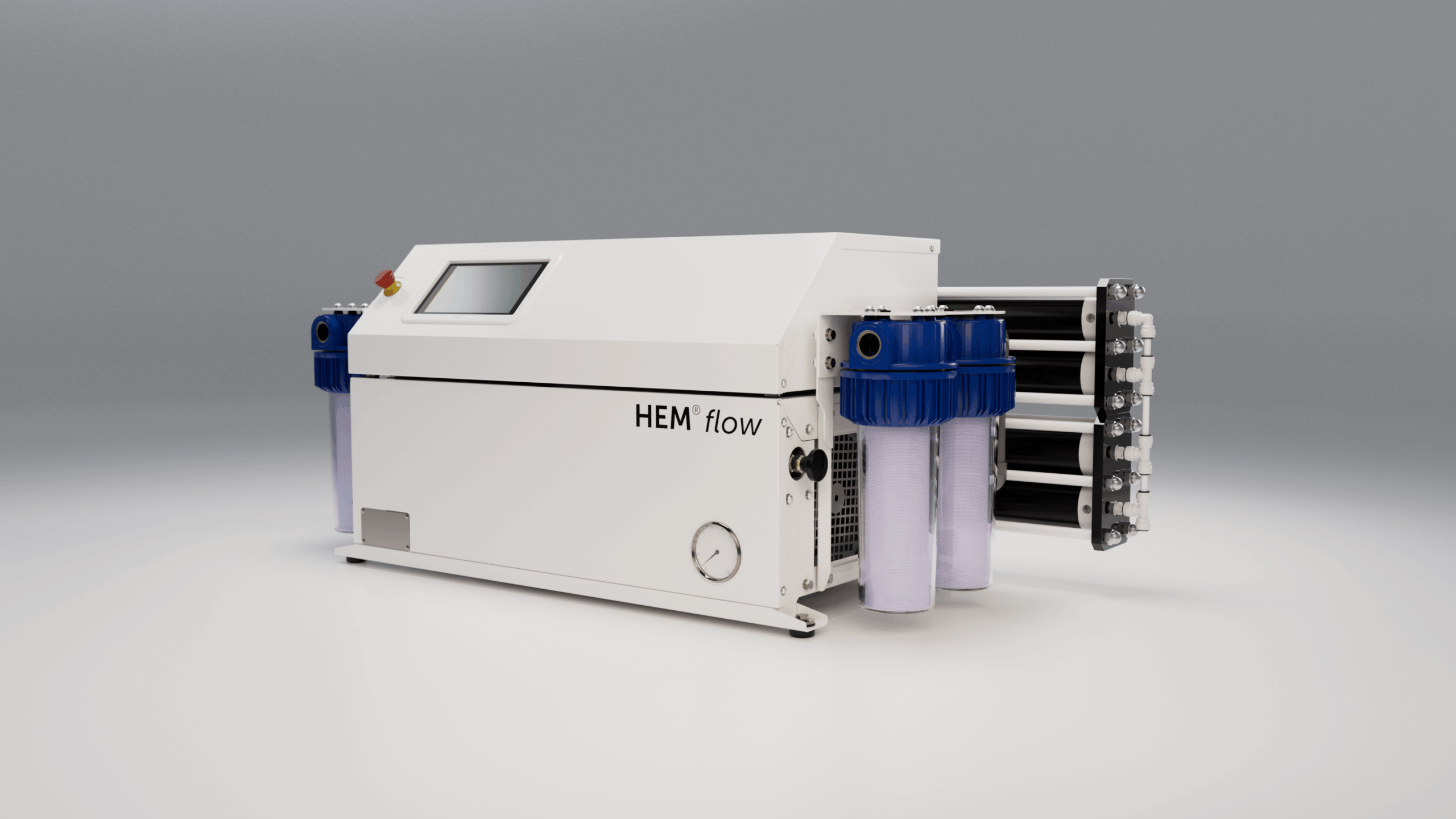

Flexible installation options

All HEM Flow models and product levels are available in two configurations.

Framed configuration

Single assembled unit

Simplifies installation

Ideal where access around the frame is available

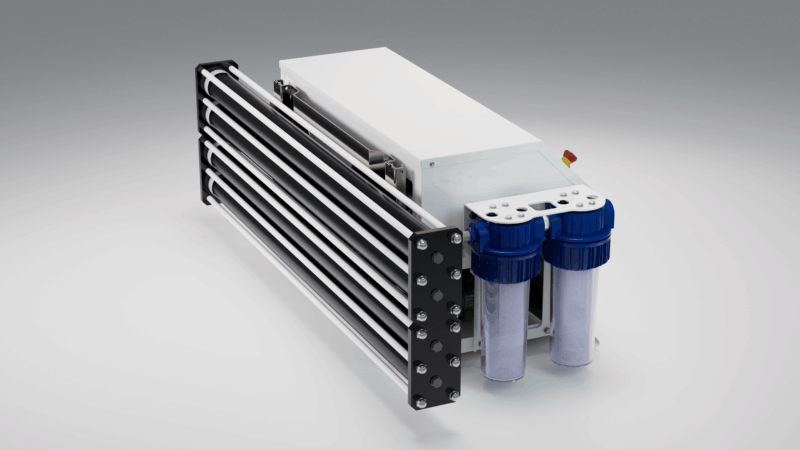

Modular configuration

Components installed separately

Fits around tight corner spaces or in narrow technical areas

Allows flexible placement of pump units and control box

Designed for yacht projects where space, reliability and cost all matter

Space, noise, installation, operating costs and ease-of-use all define whether an RO system is a good fit for the 20-50 meter yacht range.

HEM Flow models 3, 5 and 6 are designed and engineered around these specific constraints.

A new platform for compact RO systems

The new watermaker design brings HEM level reliability into a compact, easy-to-own package

HEM Flow is a new generation of reverse osmosis (RO) watermakers. Models 3, 5 and 6 are designed for yachts in the roughly 20–50 metre range.

From the simplified internal manifold to easier access to consumables, HEM Flow is shaped by everything we’ve learned from working with builders, designers, engineers and crews over decades.

It turns seawater into safe, great-tasting freshwater using proven RO technology, in a compact package that is quieter, easier to maintain, cheaper to own, and simpler to operate than many existing systems.

Lower total cost of ownership

HEM flow is priced for this size segment and is engineered to keep running costs under control.

Automatic flow control helps protect membranes and avoid unnecessary energy use, while standard, widely available components are used where practical to make spares easier to source and more affordable.

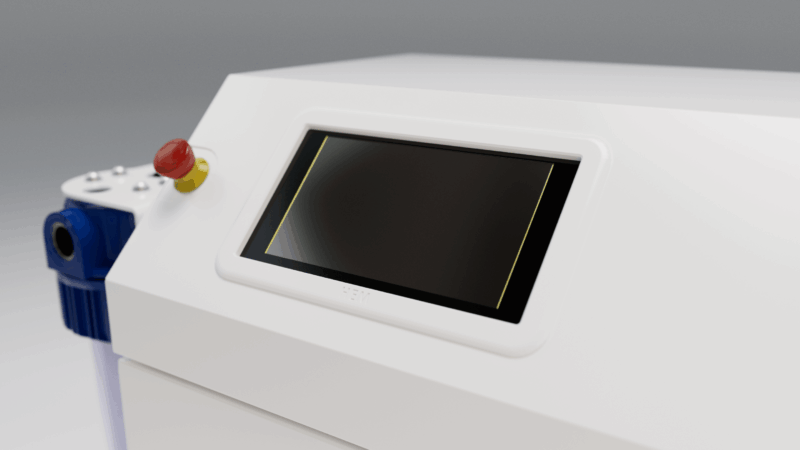

Easier operation and monitoring for crew

The HEM Flow uses a PLC-based control system with a straightforward HMI that keeps operation and troubleshooting clear.

The software manages key operating parameters, protects the system from unsafe conditions and provides visibility to the operator.

Pro versions add more advanced automation, maintenance alerts and performance trending, helping crews plan interventions instead of reacting to unexpected faults.

Service support is a key part of the HEM Flow value proposition

The system design emphasizes accessibility and the use of widely available components. This ensures stable operation throughout the vessel’s service life.

- Global service footprint through HEM and Cathelco

- Spare parts stocked regionally for short lead times

- Standardised components that remain available long-term

- Remote support capability on Pro systems via Modbus