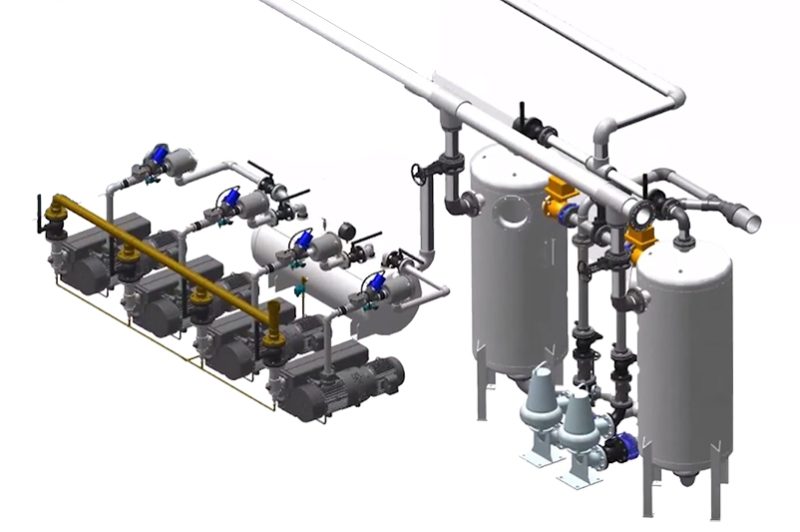

Evac´s modular vacuum collection system

Our standard vacuum collection tank series provides a range of system capacities suitable for new or renovated facilities ranging from under 20 toilets to over 2,000. All our standard models feature hands-off controls that automatically maintain system vacuum and manage sewage collection and discharge.

- For land-based applications

- Available in the North America market

- Versatile, modular design

- Versatile, modular design

- High reliability

- Multiple discharge strategies available

- High sewage retention capacity

Individual tanks of 606–3558 liters/160–940 gallons can form part of wider systems containing multiple tanks. Each tank includes three level sensor controls, multiple pump configurations (with varying pump quantities and horsepower), electric controls and panels including electrical junction box (on secondary tank), 3” or 6” ANSI flange sewage inlet connection, 3” or 4” ANSI flange sewage outlet connection (included in piping kit), and 3” or 4” ANSI flange vacuum air connection.

The primary vacuum tank’s control system enables fully automatic collection. The operator selects the operation mode for the vacuum pumps using the control panel. The system then operates automatically and there is no need for manual intervention – alarm lights will alert operators to any abnormal conditions or faults. The secondary vacuum tank provides additional holding capacity. Both tanks fill simultaneously and provide a total holding volume of 1211–7116 liters / 320–1880 gallons.

The primary and secondary tanks are interconnected with pipes in order to equalize the sewage and vacuum levels. Level sensors in each tank provide a level indication and prevent overfilling. The operation of the collection system depends on the differential air pressure between the ambient air and vacuum level in the vacuum piping and collection tanks. This pressure differential creates flow from the fixtures to the collection tank. The operating vacuum in the collection tank is normally within the range 14–18 inHg. The vacuum gauge indicates the gauge pressure, which is the pressure difference between the negative pressure in the collection tank and the atmospheric pressure.

During normal operation, air and sewage enter the collection tank from the toilets and vacuum interface valves. As the operating vacuum decreases, the vacuum sensor starts the lead vacuum pump. The vacuum pumps maintain the vacuum for the operation of the toilets and interface valves.

As sewage is collected, the vacuum decreases to 14 inHg, which starts the lead vacuum pump. The lead pump restores the vacuum to 18 inHg. The lead and lag pump alternate for each operating cycle. During peak loading conditions, the lag vacuum pump will cut in if the vacuum drops to 12 inHg. If the vacuum continues to remain below 12 inHg for 10 minutes or more, the low vacuum alarm will come on. Each vacuum pump runs for 10 minutes once there is a demand for vacuum.

The vacuum pump isolation valve automatically opens and closes to regulate the vacuum in the tank during operation. Each collection tank contains three level sensors, positioned to notify system operators when the tank is at low level (30%), high level (75%), and block level (80%). It is recommended to discharge the sewage before the tank reaches high level. When block level is reached, the system will stop running and sewage must be discharged before normal operation can resume.

Evac Lifecycle Management

For all our systems and solutions, we offer a comprehensive portfolio of services throughout the operational life of the delivered solution or equipment.