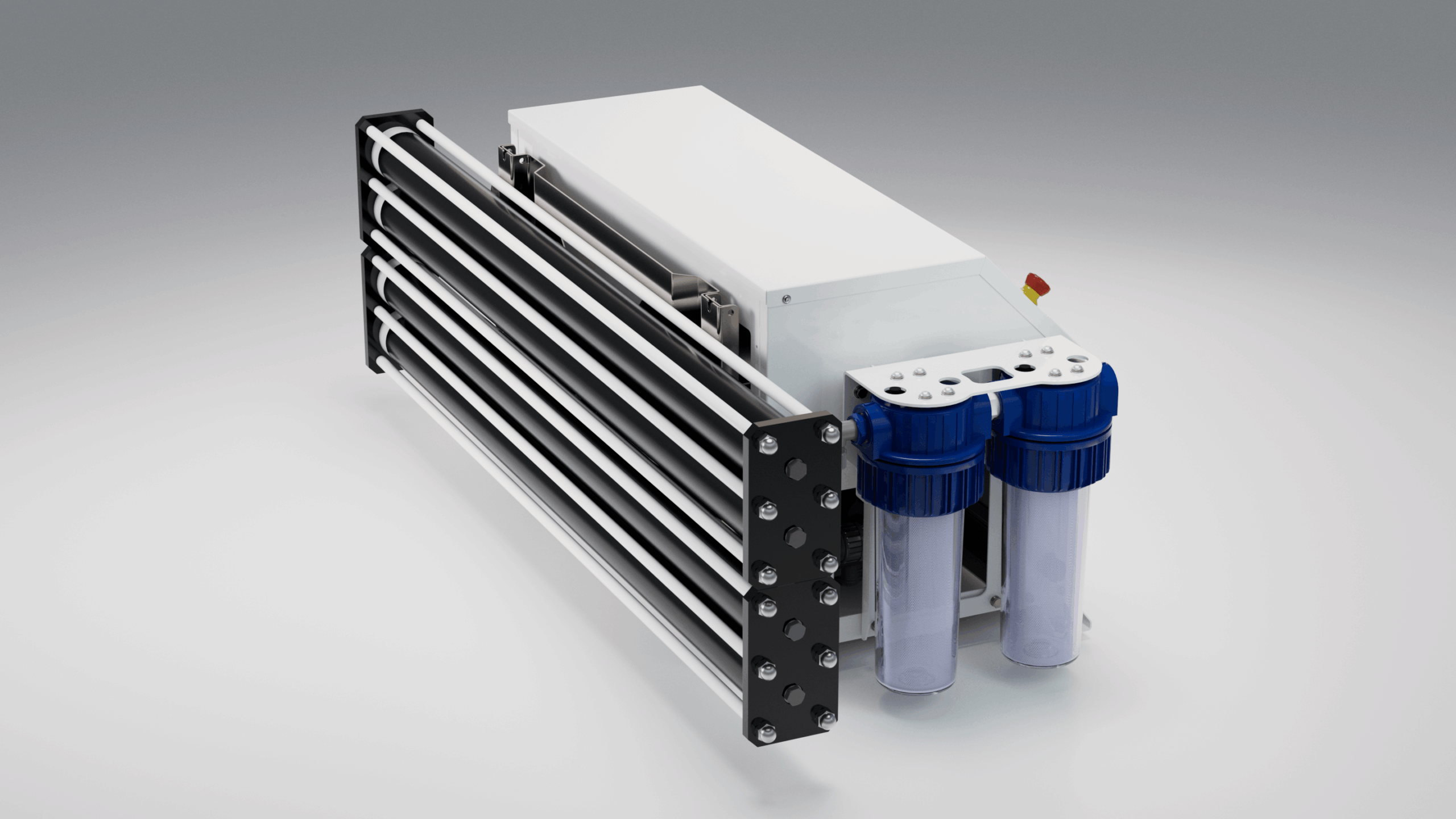

HEM Flow Series watermakers – Models 3, 5, 6

New design

- Compact and modular RO watermaker for yachts ranging 20-50 meters

- Quiet, low-vibration operation with advanced control and monitoring

- Capable of producing up to 6.6 m3 freshwater per day

The HEM Flow Series is a compact reverse osmosis (RO) watermaker range designed for 20-50 meter yacht applications where installation space, price, noise levels and long-term serviceability are key considerations.

The series uses proven RO principles combined with a modern control system and a simplified mechanical layout.

The watermakers can be fitted as framed or modular units for flexible installation.

The HEM Flow series covers typical freshwater demand for yachts in the 20–50m range.

| Model | Freshwater output |

| HEM Flow 3 | 3.7 m³/day |

| HEM Flow 5 | 5.1 m³/day |

| HEM Flow 6 | 6.6 m³/day |

Pro upgrade

The Pro upgrade adds advanced control, vessel integration, and enhanced filtration compared to the Standard version.

Smarter automatic process control

Pro regulation uses additional inputs (including product flow rate and feed water temperature) alongside salinity and operating pressure. This supports more stable operation and is intended to help prolong membrane lifespan.

Maintenance interval alerts

Standard has no interval alerts, while Pro adds configurable maintenance prompts (LP/HP pumps and membranes) based on running hours.

Remote monitoring and operation (AMCS integration)

Standard provides volt-free alarm contacts only. Pro supports full automation integration via Modbus (MODBUS TCP; IP upon request) alongside volt-free warning/alarm contacts, enabling monitoring and operation via the vessel AMCS.

Upgraded finish

Pro includes a painted, high-gloss finish as part of the upgrade package.

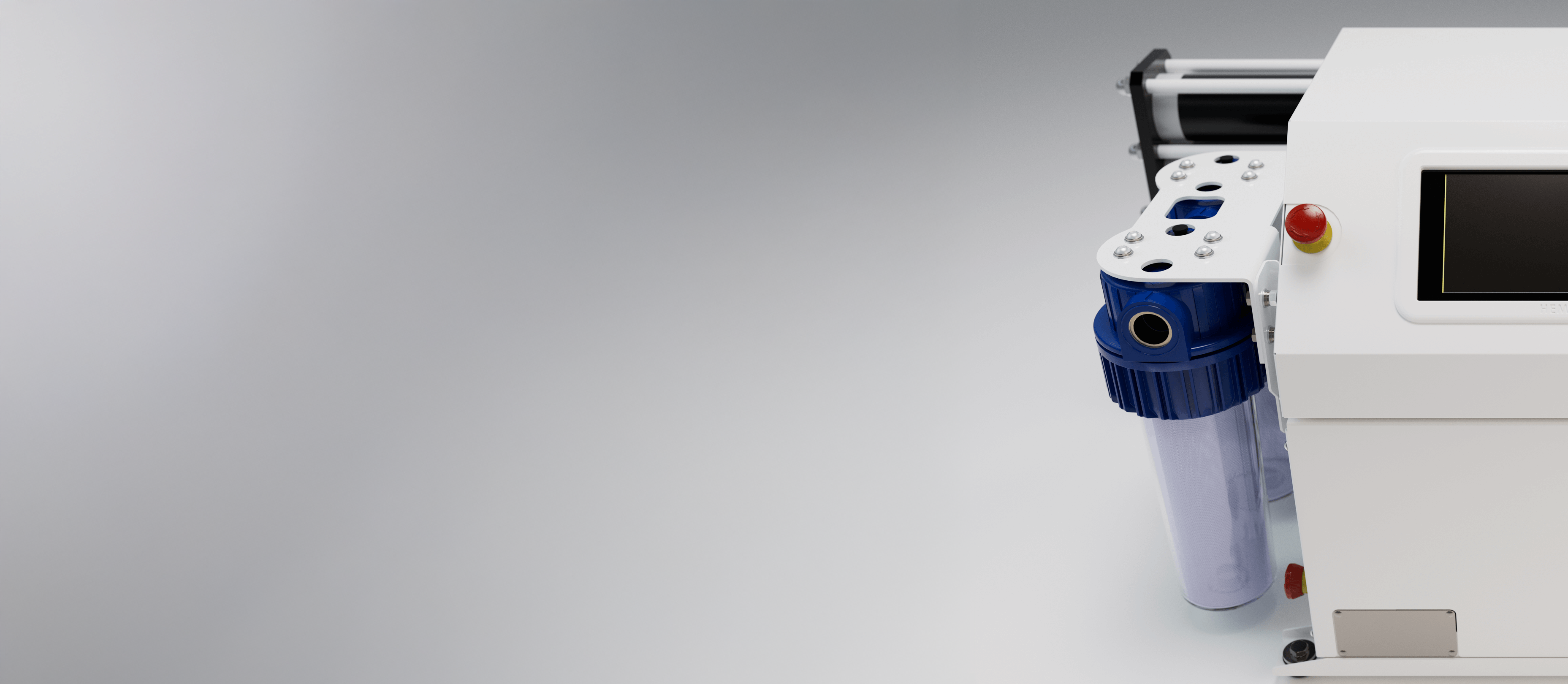

Upgraded filtration and product water conditioning

Compared to Standard, Pro adds an additional backwashable sand filter on seawater pre-filtration, and post-filtration that includes calcium carbonate granules plus active carbon to support improved palatability and pH balance.

Electrical requirements

- Electrical load: 3.1 kW

- Available voltage: 230 VAC ±10% / 1Ph / 50–60 Hz; 400 VAC ±10% / 3Ph / 50–60 Hz

- MCB size: 25A (230V / 1Ph) or 16A (400V / 3Ph)

- Grounding: install with sufficient grounding options (typically via grounding studs or pillars).

Operating parameters

- Feed water flow: 16 L/min (23 m³/day)

- Feed water pressure: 0.1–3 bar

- Working pressure: typically 55–62 bar (may vary outside this range depending on salinity and seawater temperature).

| Parameter | HEM Flow 3 | HEM Flow 5 | HEM Flow 6 |

|---|---|---|---|

| Capacity (L/min) | 2.6 | 3.6 | 4.6 |

| Capacity (L/hour) | 156 | 216 | 276 |

| Capacity (m³/day) | 3.7 | 5.1 | 6.6 |

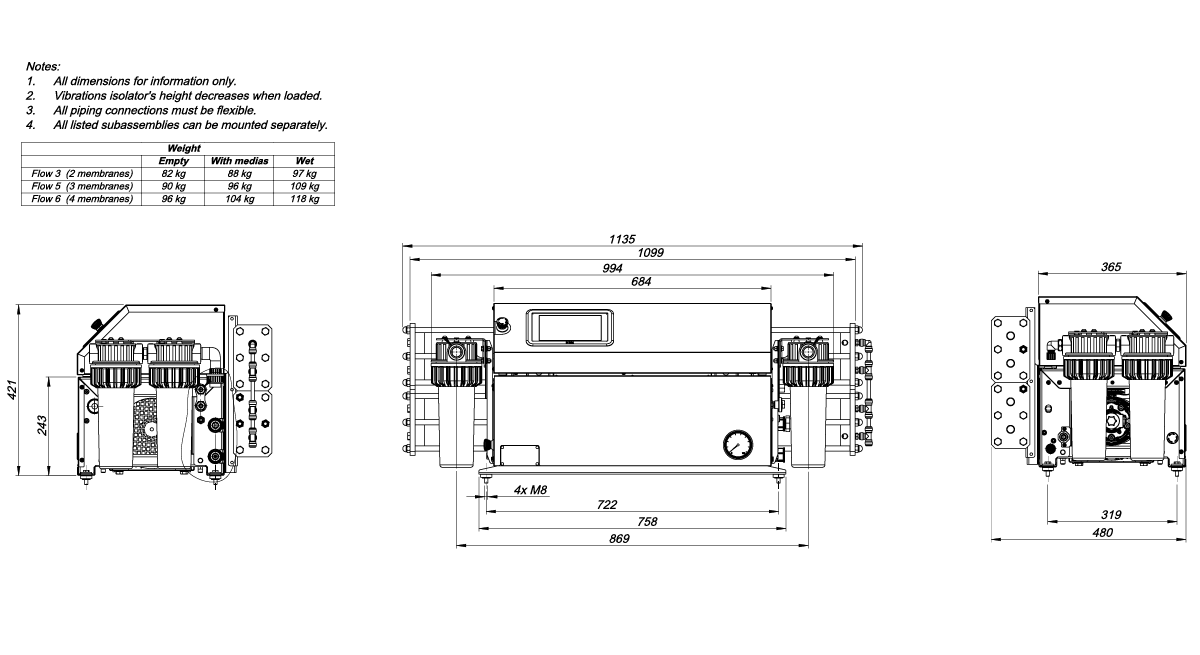

| Weight (kg) – framed | 82 | 90 | 96 |

| Weight (kg) – modular | 80 | 78 | 94 |

Safety parameters

- Low pressure switch set point: 0.1 bar (modifiable via HMI controller)

- High pressure switch set point: 70 bar (modifiable via HMI controller)

Water quality parameters

- Salt rejection: up to 99.7% (depending on operating conditions and membrane type)

- Feed water salinity: 32,000–40,000 ppm NaCl, 8–35°C (25°C optimal operating temperature)

- Product water TDS: <450 ppm

Easy access to consumables

Membranes and filters are easy to replace.

Low-vibration high-pressure pump for quieter operation

A rotary-style high-pressure pump architecture is selected to reduce vibration and noise while keeping the footprint small and maintenance needs lower than more traditional arrangements.

Simplified internal components for easier maintenance

Internal components are reduced and consolidated through a machined manifold concept to simplify the system layout and improve service access.

Soft start and stable operation through variable-speed control

A variable frequency drive enables soft start and supports stable operation by controlling the high-pressure pump.

Advanced regulation and monitoring

Automatic system process control monitors key operating variables (e.g., pressure, flow, salinity) and can provide maintenance prompts to support consistent operation and membrane care.

Vessel integration and remote control readiness

Integration outputs support connection to vessel monitoring/alarm systems, with the ability to enable deeper automation integration (including remote start/stop) where required.

Failsafe usability with full electrical override

If control electronics are compromised, a full electrical override supports continued/manual operation.

Which model fits your project?

Multiple variations and configuration options make HEM Flow easy to spec and fit for any project.

Try the HEM Flow configurator to see which model and variation is the right one for you.

Recommended setup

Contact HEM sales

Share your details and we’ll route the configuration to our team.

Service support is a key part of the HEM Flow value proposition

The system design emphasizes accessibility and the use of widely available components. This ensures stable operation throughout the vessel’s service life.

- Global service footprint through HEM and Cathelco

- Spare parts stocked regionally for short lead times

- Standardised components that remain available long-term

- Remote support capability on Pro systems via Modbus