Pacific Basin selects Cathelco’s USP DragGone™ ultrasonic antifouling for propeller efficiency

When it comes to maintaining fleet efficiency, even small efficiency losses can have outsized consequences. That’s why Pacific Basin Shipping, one of the world’s leading dry-bulk operators, has chosen Cathelco’s USP DragGone™ ultrasonic antifouling system for installation on the MV Fortune Island.

The system will be fitted to the vessel’s propeller, a focus area where performance gains translate directly into fuel savings. For Pacific Basin, the decision forms part of a broader effort to improve propulsion efficiency and reduce maintenance frequency across its fleet.

Operating globally and managed from Hong Kong, Pacific Basin was looking for a low-intervention solution that complements its existing maintenance routines. Propeller polishing, while effective in the short term, offers only temporary relief from the performance losses that gradually build up as marine growth takes hold on the propeller.

“This is a strong technical fit,” says Chris Bell of Cathelco. “Pacific Basin was evaluating several technologies, and we were able to demonstrate both the engineering credibility and operational simplicity of DragGone™, supported by our long-standing relationship supplying ICCP and MGPS systems to their fleet.”

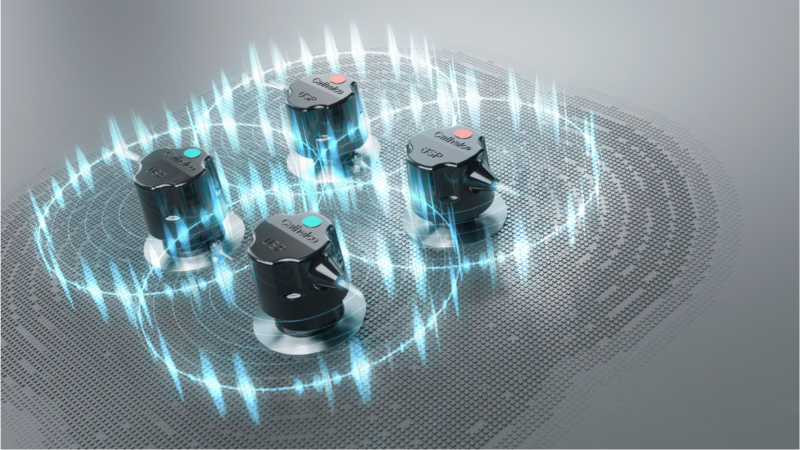

The installation is scheduled to take place during an upcoming dry-dock later this year. The DragGone™ configuration will feature a set of transducers arranged specifically to cover the propeller hub and blades, ensuring consistent ultrasonic propagation throughout the structure.

Finding a solution to an expensive and recurring challenge – propeller fouling

For ship operators, propeller fouling is a deceptively expensive problem. Even minor roughness on the blade surface can undermine a vessel’s propulsion efficiency within weeks of a dry-dock.

Pacific Basin’s technical team identified this as a recurring issue, one that conventional cleaning schedules could not fully address. Their decision to install DragGone™ shows a practical response from a responsible owner: finding a way to sustain propeller performance between maintenance intervals and cut back on reactive cleaning.

Cathelco’s ultrasonic technology provides continuous, non-biocidal protection, using ultrasonic sound waves to prevent biofilm and marine growth formation on submerged surfaces before they can attach. It eliminates the downtime and recurring cost associated with in-water cleaning, while aligning with tightening IMO and regional biofouling standards.

“They wanted a solution that drives operational savings without adding complexity or chemical treatment,” Bell explains. “That’s exactly where DragGone™ delivers value.”

The data behind the decision

Built in Japan in 2010, Fortune Island is a 61,484-DWT Ultramax bulk carrier operating under the Hong Kong flag. Although slightly older than Pacific Basin’s fleet average, the vessel continues to outperform many of its peers, with an estimated carbon intensity of 4.51 g CO₂ per dwt-mile, roughly five percent below the average for vessels of similar size and age.

Classed as an ECO vessel by Clarkson’s World Fleet Register, the ship incorporates several energy-saving technologies (ESTs) that support its strong operational profile. Yet, like most vessels, maintaining that performance over time depends on keeping marine growth under control, particularly on the propeller and other hard-to-reach areas, where fouling increases fastest.

Independent studies have shown that even light propeller fouling can reduce efficiency by 3–6 percent, forcing engines to burn 3–8 percent more fuel to sustain the same speed. In severe cases, fuel use can rise by 15–25 percent, while service speed drops by up to 1.5 knots. Because propellers tend to foul faster than hulls, especially in warmer waters and low-speeds, keeping them clean provides a disproportionate return in both fuel and emissions performance.

By continuously preventing marine growth attachment ultrasonic antifouling helps vessels maintain smooth, clean propellers. The result is more stable power demand and predictable fuel consumption.

A step toward consistent fleet-wide efficiency

The project is an example of how ultrasonic antifouling strengthens overall vessel efficiency by addressing biofouling before it starts, across both hull and propeller. Even with effective coatings, growth can return between dockings, gradually increasing drag and fuel consumption.

By keeping these surfaces clean through continuous, non-biocidal protection, DragGone™ helps vessels maintain smoother hydrodynamics for longer periods. For Pacific Basin, the installation supports a consistent performance baseline across its trading routes, while for Cathelco, it demonstrates how ultrasonic technology complements existing antifouling strategies to deliver lasting efficiency gains.

Cathelco, part of the Evac Group, is a world leader in marine growth prevention and corrosion-protection technologies. Its portfolio includes USP DragGone™ ultrasonic antifouling, marine growth prevention systems (MGPS), and impressed current cathodic protection (ICCP) solutions serving global commercial, cruise, and offshore fleets.

Key facts

Client

Pacific Basin

Build year

2010

Vessel Type

Ultramax Bulk Carrier

Cathelco Solutions

USP DragGone™