Say hello to the next-generation of ultrasonic antifouling

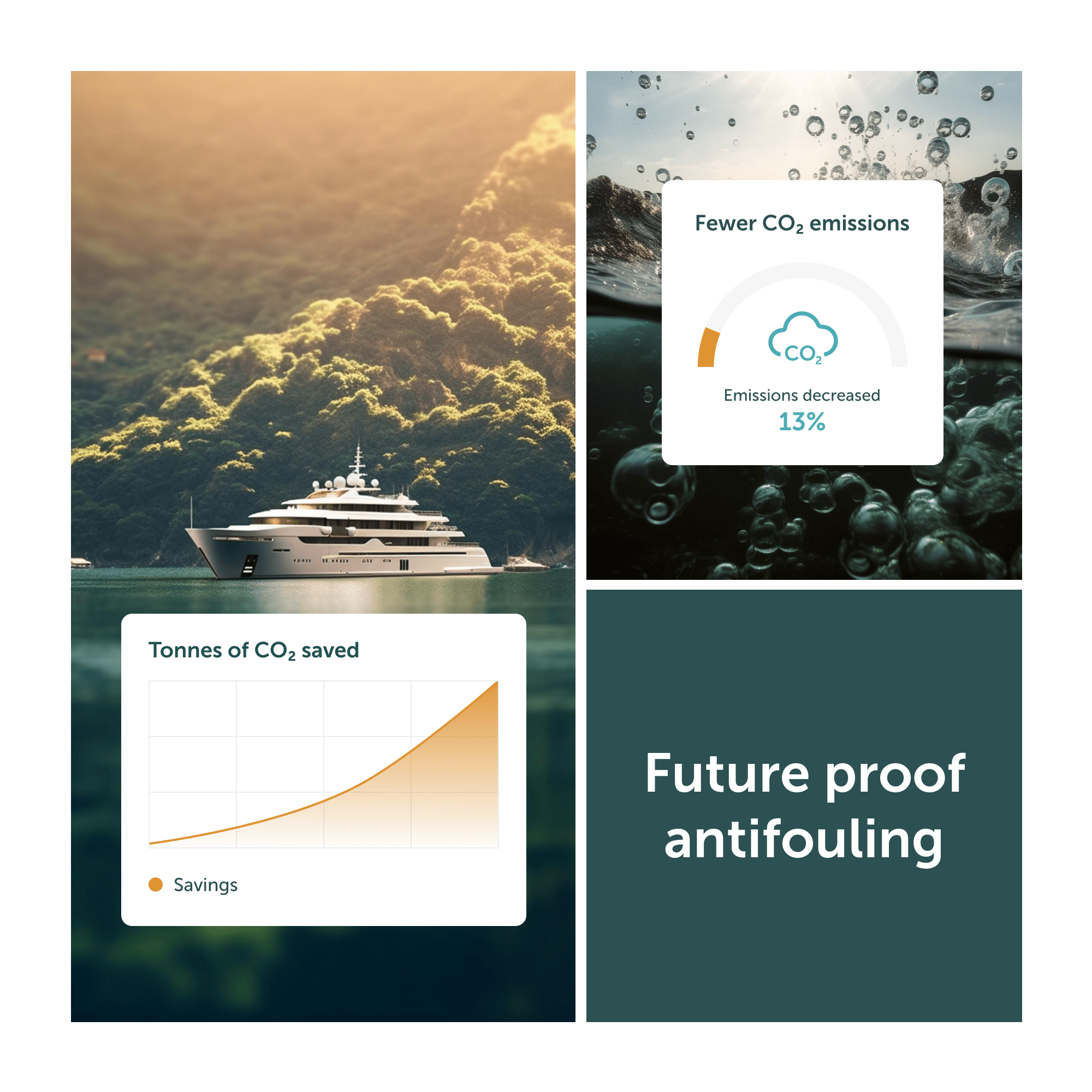

Achieve up to 13% reduction in fuel consumption

DragGone™ keeps your hull free of fouling, improving hydrodynamic performance and vessel fuel economy for cost-effective operations.

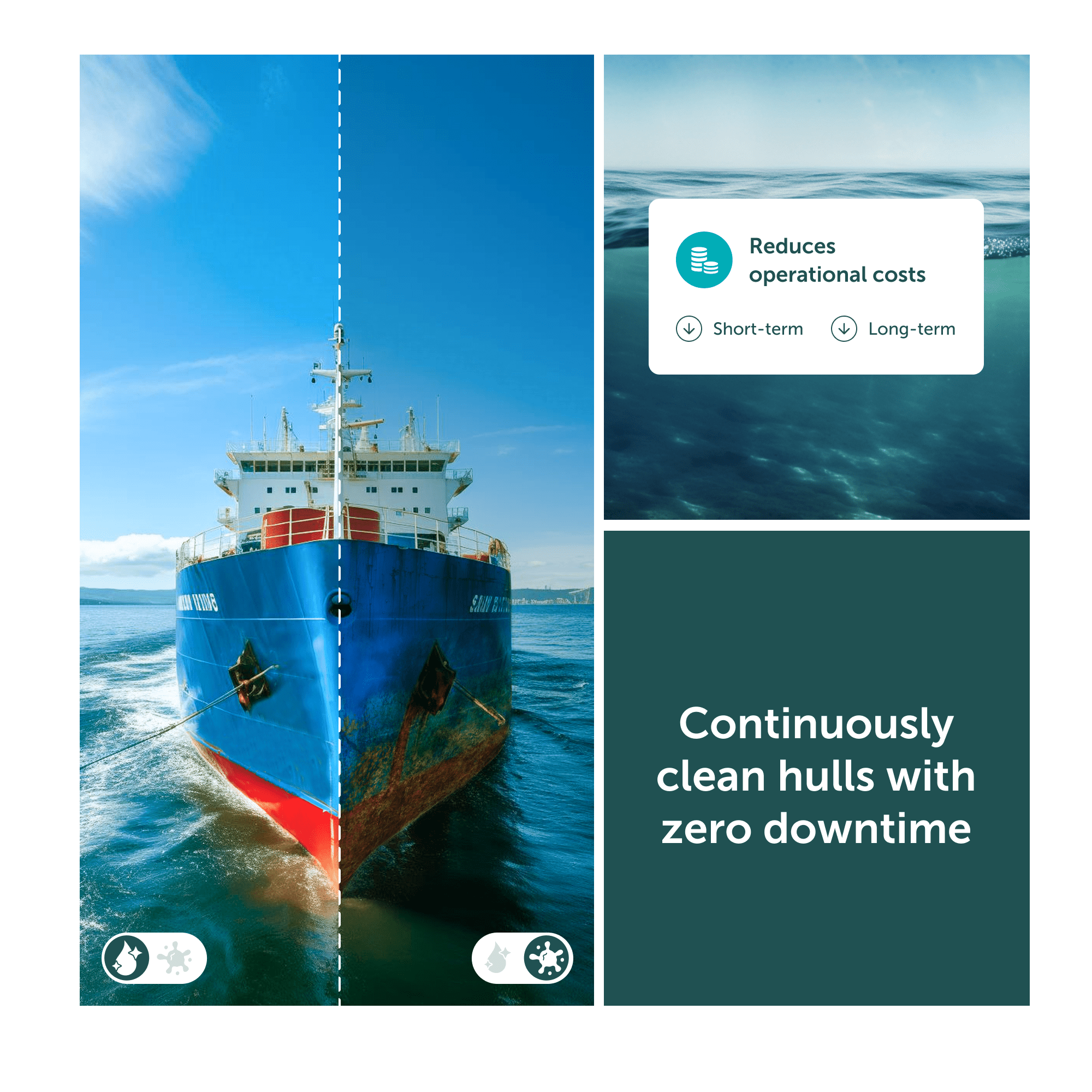

Keep hulls clean

without the extra work

DragGone™’s proactive protection against hull fouling cuts down on associated cleaning costs and extends vessel service life.

Cut emissions, safeguard ecosystems

Allows you to significantly reduce greenhouse gas emissions and prevent the spread of invasive aquatic species with a fully non-biocidal solution.

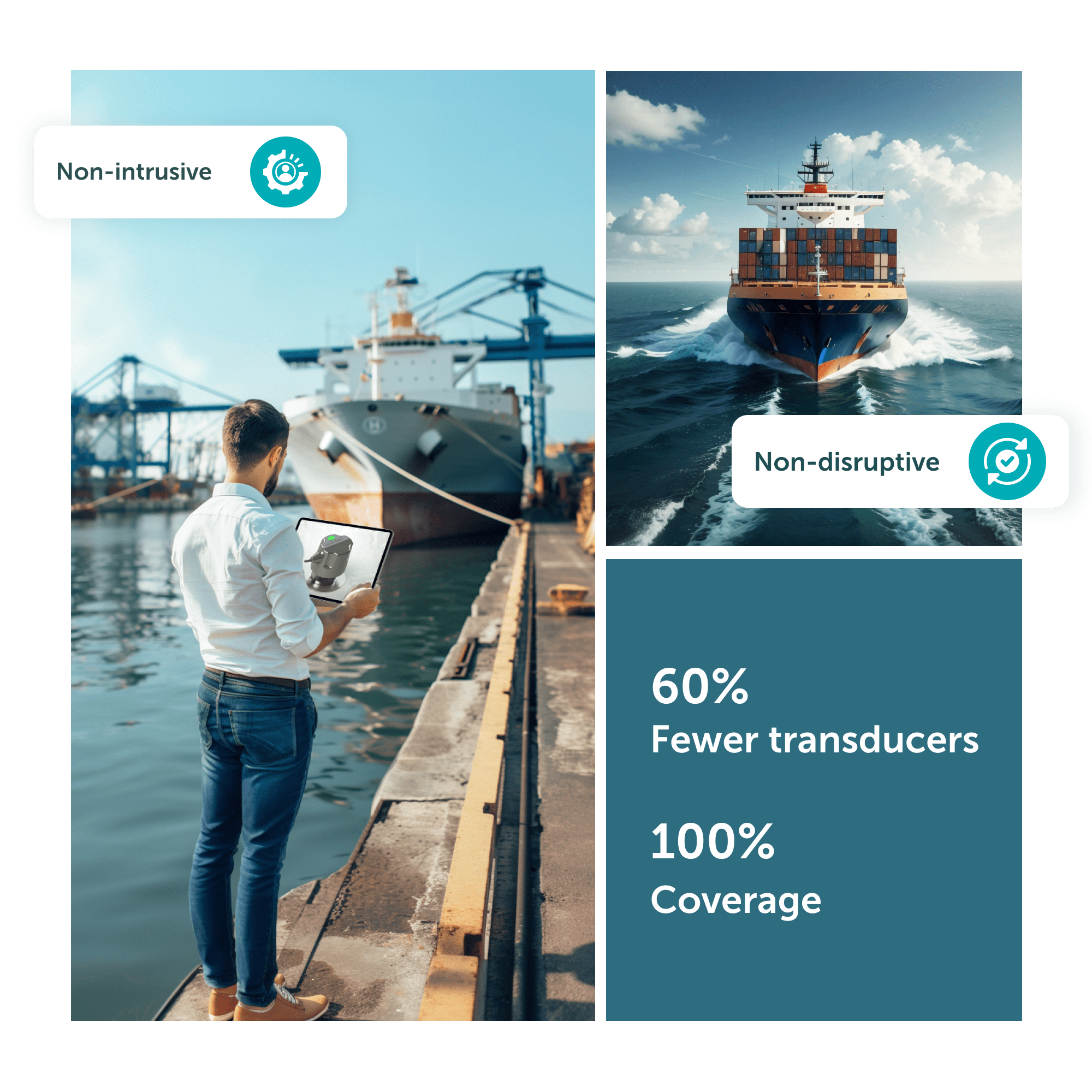

Patented

ultrasonic technology

Patented technology allows for more efficient and effective treatment of biofouling. Requires 60% fewer transducers for full hull coverage.

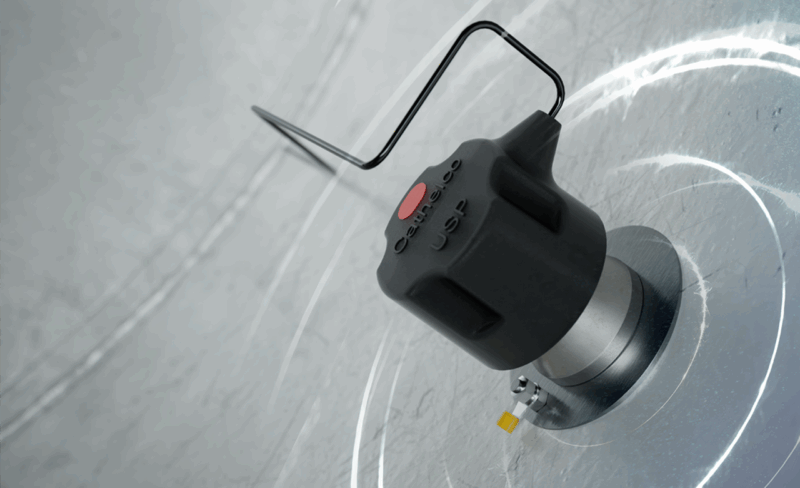

New capability: Waterproof transducer installations for wet spaces

On some large commercial vessels, ultrasonic antifouling coverage has been limited because transducers traditionally need a dry inner-hull mounting area. When large sections of the inner hull sit within ballast tanks and other wet spaces, it can be difficult to place transducers where they’re needed for broad waterside coverage.

This matters because untreated hull sections can still foul. Even localised fouling increases drag, which typically leads to higher fuel consumption and higher greenhouse gas emissions than could be achieved with better coverage.

Enables installations in wet areas (for example ballast tanks, water tanks and bilge tanks), where access and placement would otherwise be restricted.

Modular by design: specify cofferdams only for the transducer locations that need waterproofing.

Discover ultrasonic antifouling for different vessel types

NEXT-GENERATION ULTRASONIC ANTIFOULING

USP DragGone™ provides enhanced ultrasonic antifouling protection

Say goodbye to hull fouling. You can finally address both the environmental and economic challenges posed by biofouling:

- Increased fuel consumption and CO2 emissions

- The spread of invasive species

- Reduction in service life

DragGone™ is your frontline defense against biofouling, effectively preventing the accumulation of microorganisms, plants, algae, and marine animals on the hull of your vessel, enhancing the hydrodynamic performance and corrosion resistance of your vessels, and contributing to their durability and functionality.

Read more about the economic impact of ultrasonic antifouling systems

Superior ultrasonic antifouling against hull fouling

Maximize your fleet’s efficiency with our patented ultrasonic antifouling system

DragGone™ harnesses the power of patented technologies to offer unparalleled biofouling protection.

Guided Wave technology channels ultrasonic energy along structures, such as hull plates for an enhanced range of protection. Heterodyning technology creates multiple frequencies to target a wider spectrum of fouling organisms effectively.

This dual approach ensures superior protection and reduces the need for transducers by 60%, significantly cutting down on maintenance, cleaning costs, and overall operational expenses.

Non-Toxic Operation

Safeguard your vessels with eco-conscious ultrasonic antifouling solutions

Tackling biofouling head-on, DragGone™ improves your vessels’ fuel efficiency and contributes to reducing your environmental footprint.

By cutting fuel consumption and emissions, you’re stepping up as a leader in sustainable maritime operations, demonstrating that economic savings and environmental responsibility can sail side by side.

Read more about the environmental benefits of ultrasonic antifouling

Easy Installation and Maintenance

Simple to get started, with results from day one of installation

We understand the value of your time and resources.

That’s why DragGone™ is designed for effortless installation and low maintenance, allowing you to deploy the system quickly and without the need for dry-docking or hull penetrations. This ease of installation and minimal upkeep translate to more time focusing on what truly matters—running your fleet efficiently and effectively.

Read more about choosing the best antifouling options for your fleet

Ready to see how much you can save with DragGone™? Try the Fuel and Emission Impact calculator!

Operational Readiness and Efficiency

Keep your fleet ready and reliable around the clock

With DragGone™, say goodbye to frequent and costly hull scrubbings and the downtime they bring.

Our system ensures your vessels stay in prime condition for longer, boosting operational readiness and efficiency. It’s all about allowing your vessels to adhere to their schedules and meet commitments without disruption.

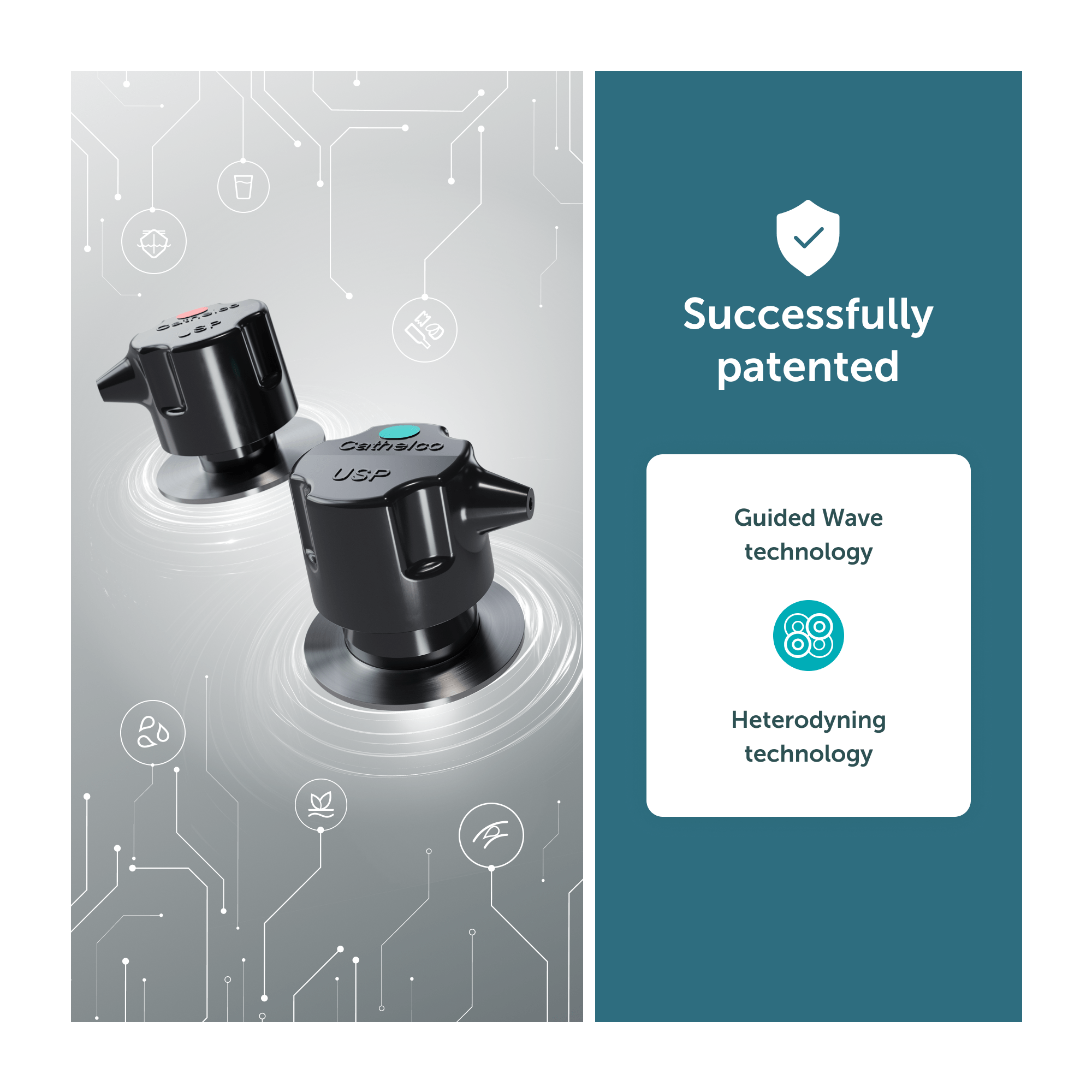

The DragGone™ difference: Patented technology

Heterodyning Technology

European Patent – EP3774519

US Patent – US 11,186,349 B2

Canadian Patent – 3,078,640

Creates multiple frequencies to target a wider spectrum of fouling organisms more effectively

Protects against species attachment in diverse environments

Can enhance the hydrodynamic performance of your vessels

Guided Wave Technology

European Patent – EP3774519

US Patent – US 11,186,349 B2

Canadian Patent – 3,078,640

Channels ultrasonic energy along structures, such as hull plates for an enhanced range of protection

Allows for efficient disruption of biofouling attachment over greater distances

Results in up to 60% fewer transducers needed for complete protection, simplifying installation and operation

Upgrade to the Next-Generation of

Ultrasonic Antifouling

Frequently asked questions about ultrasonic antifouling

How does ultrasonic antifouling work?

Ultrasonic antifouling operates through acoustic cavitation, where high-frequency sound waves create microbubbles that burst, generating local pressure to inhibit biofouling. This process ruptures the cells of microorganisms, preventing attachment on the hull’s surface and maintaining a cleaner vessel structure.

Does ultrasonic antifouling require dry-docking for installation?

Typically, ultrasonic antifouling systems do not require dry-docking. Transducers are mounted on the interior side of the hull, avoiding hull penetration and enabling efficient installation while the vessel remains in service.

What are the benefits of multi-frequency ultrasonic technology?

Multi-frequency ultrasonic technology is designed to tackle a diverse range of biofouling organisms by operating across multiple frequencies, ensuring broader, more effective biofouling prevention. Unlike single-frequency systems, multi-frequency systems adapt to different organism types, improving hull cleanliness and operational efficiency.

Can ultrasonic antifouling be used alongside other biofouling prevention methods?

Yes, ultrasonic antifouling can complement other methods, such as cathodic protection and marine growth prevention systems. When combined, these systems offer a robust solution for vessels in challenging, high-fouling environments, enhancing the overall biofouling defense strategy.

Is ultrasonic antifouling environmentally safe?

Ultrasonic antifouling is a non-toxic alternative that avoids biocidal chemicals. Instead, it uses sound waves to disrupt biofouling attachment processes, aligning with IMO regulations and supporting sustainable marine practices by protecting biodiversity.

What key features define an effective ultrasonic antifouling system?

Effective ultrasonic systems leverage multi-frequency technology to combat a broader spectrum of biofouling organisms. Advanced systems, like Cathelco’s DragGone, utilize patented guided wave and heterodyning technologies, maximizing coverage with fewer transducers and enhancing overall biofouling prevention efficiency across extensive hull surfaces.

Contact ultrasonic antifouling sales

Our expert team is here to guide you through our Ultrasonic Antifouling Solutions tailored to your specific needs.