What is a sacrificial anode and why ICCP systems are a better solution?

If you’ve spent time at sea, you’ve likely dealt with chipped paint, rust, and corrosion more than once. As you know, steel and seawater are a challenging combination. Over time, seawater promotes corrosion, and while protective coatings help, they can deteriorate or become damaged and cannot eliminate corrosion risk entirely, particularly on submerged areas such as the hull.

One common method used to protect the hull is sacrificial anodes. These are shaped metal blocks attached to the hull that are designed to corrode in preference to the hull steel, reducing the rate of hull corrosion.

The limitation is that sacrificial anodes are consumable and must be replaced as they wear away. In addition, once installed, their performance is largely determined by the anode material, the number and size of anodes, and the water conditions in which the vessel operates. They cannot be adjusted day to day.

For this reason, most operators choose impressed current cathodic protection (ICCP) instead, or together with sacrificial anodes. ICCP uses powered anodes and reference electrodes to monitor the electrical potential at the hull/seawater interface and automatically adjust electrical output to maintain the appropriate level of hull protection as conditions change.

Let’s explore what a sacrificial anode is, how it works, and why ICCP systems can be a better alternative.

What is a sacrificial anode?

Sacrificial anodes are devices designed to prevent the corrosion of metal surfaces, especially those exposed to electrolytes like seawater. The term itself is self-explanatory. These anodes create a galvanic anode cell, where the anode “sacrifices” itself to protect the cathode from galvanic corrosion.

Sacrificial anodes consist of more reactive metals, which means they corrode preferentially, thereby sparing the less reactive materials they attach to. This way, they maintain the functionality of marine equipment and ensure a longer (and corrosion-free) lifespan for more important metals of ships and underwater structures.

Besides ships and underwater structures, sacrificial anodes also work wonders in preventing corrosion in water heaters, pipelines, and tanks.

In water heaters, the sacrificial anode is the metal rod that prevents the tank from corroding and eventually corrodes itself. The same is the case with both above-ground and underground tanks.

How do sacrificial anodes work?

Sacrificial anodes work through a galvanic (electrochemical) redox process: oxidation happens at the anode, while reduction reactions occur on the protected metal surface.

When a sacrificial anode is electrically connected to a metal structure (like a steel hull) in seawater, the two metals and the seawater form a galvanic cell. The anode becomes the active metal and the hull becomes the cathode. Electrons released as the anode corrodes flow to the hull, keeping the hull surface cathodic and suppressing its corrosion.

Simply put, the sacrificial anode corrodes instead of the hull.

So how does a sacrificial anode prevent corrosion? It comes down to the natural electrochemical difference between the two metals. Sacrificial anodes are made from metals with a more negative electrochemical potential than the metal they’re protecting, so they preferentially oxidize and “take the hit” first.

What are anodes made of?

Sacrificial anodes are typically made from zinc, aluminium, or magnesium alloys. These alloys are more anodic (more active) than steel, so they corrode preferentially and protect the structure.

Between the two main seawater options, aluminium anodes are widely used and can be cost-effective because they typically have a lower consumption rate than zinc for an equivalent protection requirement. Zinc anodes are also widely used in marine service and remain a common, proven choice for seawater protection.

What are the disadvantages of sacrificial anodes?

While sacrificial anodes work great, they do have their own set of limitations. These limitations can affect their overall performance and lifespan, making them unsuitable for certain applications.

Short lifespan

One of the main drawbacks of sacrificial anodes is their short and often unpredictable lifespan. Depending on the material and environmental conditions (like seawater temperature), they may need replacement in as little as six months.

High chloride levels in seawater can also reduce the effectiveness and lifespan of sacrificial anodes. That rapid degradation means they need to be replaced frequently, which can be time-consuming and costly.

Limited current output

Sacrificial anodes also have limited current output. The amount of current an anode can produce is directly proportional to its weight. On larger ships, that can be a big issue as the demand for current capacity may exceed what the anode can realistically supply without adding excess weight.

That means sacrificial anodes aren’t always suitable for large metal structures or those that require high current output.

Hard to replace

Replacing sacrificial anodes can be difficult, especially in hard-to-reach locations.

For example, while the vessel is underway you will not be able to easily access the anodes for replacement. Even if you can, the process can be time-consuming and involves divers performing surface preparation and underwater welding. That adds to the maintenance burden and increases operational costs due to the need for additional labor.

The benefits of ICCP systems over sacrificial anodes

Unlike sacrificial anodes, ICCP systems have better control and performance, and more precise current control. This means optimal corrosion protection even with changing seawater conditions like temperature and salinity.

Here are more benefits of ICCP systems:

Longer life

ICCP systems use inert anodes powered by an external current source, so they don’t corrode like sacrificial anodes.

While sacrificial systems typically need replacement every 1 to 3 years, ICCP systems can operate for much longer, up to 15 years. This reduces maintenance, drydock time, and long-term costs.

That alone makes ICCP systems a better option for long-term corrosion protection.

Adaptability to complex structures

ICCP systems require fewer anodes and provide precise current control, unlike sacrificial anodes, which rely on mass to generate protective current. This makes ICCP ideal for large or complex hulls.

The system adjusts automatically to changing seawater conditions, delivers even protection, and can be maintained without drydocking, saving both time and resources.

Sacrificial anodes usually struggle to provide even protection due to “shading” effects. Meanwhile, impressed current cathodic protection systems can be custom designed to meet the specific needs of complex structures. This enables them to prevent corrosion more effectively than traditional methods.

In short, ICCP systems are highly adaptable to complex structures, making them ideal for offshore platforms and large vessels with complicated hull forms.

Lower lifecycle cost

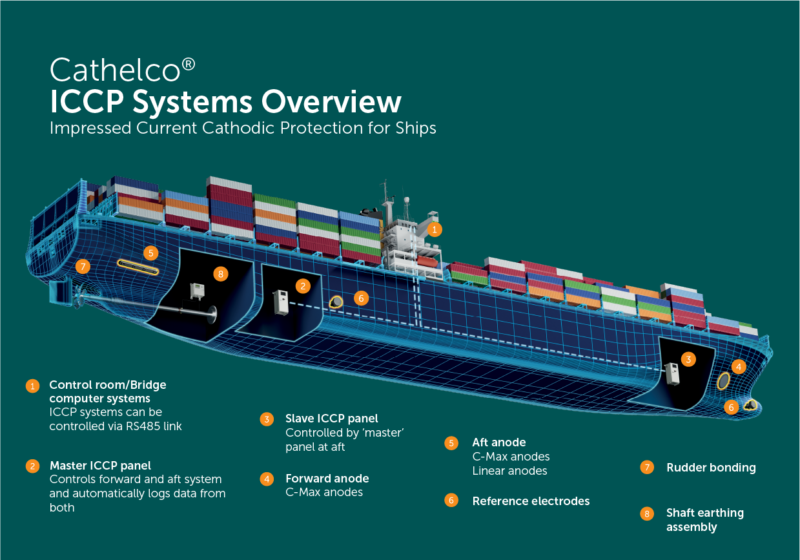

Although ICCP systems typically cost more upfront, that’s because you’re buying an active, monitored protection system, not just metal anodes. A typical ICCP package includes a control panel (power/control unit) plus hull-mounted anodes and reference electrodes that continuously measure hull potential and automatically raise or lower anode output to maintain the optimum level of protection.

Over the long term, that added equipment delivers value through more precisely controlled protection and long service life (for example, Cathelco’s flush-mounted ICCP anodes have a design life of around 15 years, far longer than sacrificial anodes).

If you want to keep your ship corrosion-free and within budget, ICCP systems are a good investment. You can reduce operational expenditure on replacements and maintenance.

Upgrade to ICCP with Cathelco

ICCP technology is designed to reduce maintenance costs by protecting ship hulls and offshore structures from corrosion. Using hull-mounted anodes and reference electrodes, the system monitors hull potential and automatically adjusts current output to maintain the right level of protection as conditions change.

If you’re evaluating ICCP for your fleet or newbuilds, you can explore the options and specifications in our materials: view the product catalog online, or download the Cathelco ICCP brochure for a clear overview of system configurations and components.

Download the ICCP product brochure