Why It’s Time to Rethink Hull Maintenance

Vessel operators face constant pressure to balance efficiency, compliance, and cost, often with limited time and resources. While traditional hull maintenance methods feel familiar, they come with hidden costs and avoidable risks. This article explores how coatings can be combined with proven proactive systems like ultrasonic antifouling and ICCP to simplify operations, reduce fuel use, and support long-term performance.

In the maritime industry, vessel operators carry the weight of critical responsibilities. They are the ones dealing with the realities of port state regulations, managing operational efficiency, and delivering results under mounting economic pressures. They often rely on tried-and-true methods that feel reliable because they have been used for decades. But when it comes to hull maintenance, there is a better way, a way that aligns with operators’ goals and simplifies their already demanding jobs.

Proactive hull maintenance systems, such as ultrasonic antifouling, and Impressed Current Cathodic Protection (ICCP), offer operators a chance to move beyond the time-consuming and costly cycle of reactive cleaning. These systems are not untested; they are proven solutions with decades of operational success behind them. The question is not whether they work. The question is: how can we help operators feel confident that these tools will truly make their jobs easier?

Making the Hull Maintenance Job Easier, Not Harder

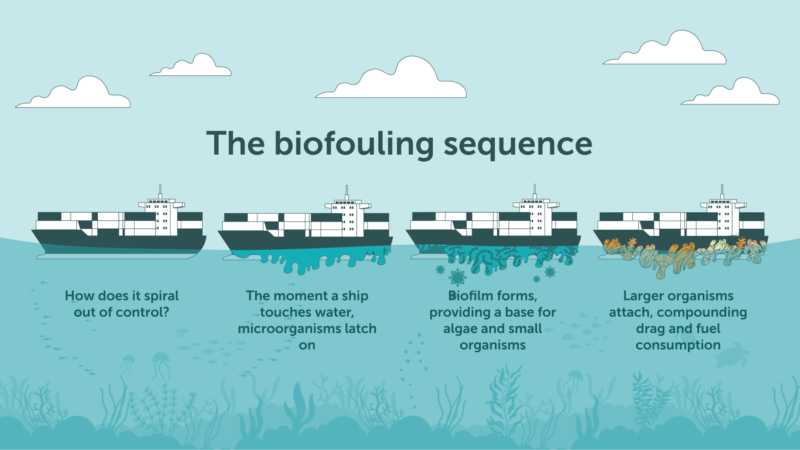

Vessel operators and owners are not opposed to change for its own sake. They are focused on doing their jobs, keeping vessels efficient, compliant, and profitable. When a ship spends months accumulating biofouling, operators know that increased drag leads to higher fuel consumption, more CO2 emissions, and costly dry-docking and cleaning. Yet, despite these inefficiencies, many stick to reactive cleaning because it is familiar, predictable, and requires no upfront decisions.

But this approach is resource-intensive, sometimes wasteful, and risky. Reactive cleaning can damage hull coatings, shortening their lifespan and increasing long-term costs. Proactive systems like ultrasonic antifouling, however, prevent fouling from forming in the first place. These solutions keep hulls clean and systems running efficiently without the need for constant intervention.

For operators, this means less time managing emergencies and fewer disruptions to schedules. It means fewer costly surprises and more predictable maintenance planning. Most importantly, it means being able to focus on what matters: running vessels efficiently and reliably.

Overcoming Hesitations

Despite the clear benefits, it is easy to understand why some operators are hesitant to adopt the more novel systems. Change always involves a degree of uncertainty, and the maritime industry’s cautious culture reinforces the tendency to stick with what is known, and often for good reason

The hesitation often boils down to three concerns:

- Operators need assurance that proactive systems will deliver results in their specific operating conditions. They want to see clear, reliable data, backed by real-world examples.

- Upfront costs for proactive systems can seem high compared to the immediate costs of a single cleaning job. Without a clear understanding of the long-term savings, it can be difficult to justify the expense.

- Operators worry about how new systems will integrate with their vessels, whether they will require additional training or maintenance, and how they might affect existing workflows.

Proactive Hull Maintenance Designed for Operators

The truth is, proactive hull maintenance systems are designed to solve precisely these challenges. They are not experimental technologies, they are tried and tested tools with a proven track record of delivering value to operators.

These systems are easy to install, require minimal maintenance, and deliver long-term savings that far outweigh their initial costs. They reduce the need for reactive cleaning, freeing up resources and time that operators can invest elsewhere.

Why This Matters Now

The pressure on vessel operators is intensifying. Regulatory demands are growing, fuel costs are rising, and the industry is facing unprecedented challenges in decarbonization and sustainability. Every decision counts.

Proactive hull maintenance offers a practical, immediate way to ease these pressures. It provides operators with tools that align with their priorities of efficiency, compliance, and cost-effectiveness, while also supporting broader industry goals.

A Partnership, Not a Burden

The success of proactive maintenance systems depends on partnership. Suppliers must play a central role in making adoption easy for operators. This means that suppliers must share clear, comprehensive evidence of how these systems work, with case studies, ROI data, and testimonials from operators in similar circumstances.

Proactive systems must be designed for seamless installation and operation, with minimal disruption to schedules or workflows. Training, maintenance, and customer service should be readily available to ensure operators feel confident using the systems.

These are not insurmountable barriers, but opportunities for suppliers and operators to work together toward a shared goal: better, more efficient, and more sustainable vessel operations.

Empowering Operators to Lead the Way

At its core, proactive hull maintenance is about empowering operators. It’s about giving them the tools to do their jobs more effectively, freeing up their time, reducing their stress, and improving their bottom line.

Operators don’t need to be convinced that efficiency matters. They already know the stakes. What they need are solutions that fit seamlessly into their operations, with clear evidence that these systems will deliver on their promises.

By focusing on what operators need: support, simplicity, and reliability, we can accelerate the adoption of proactive maintenance systems and unlock their full potential.

The tools are here. The systems are proven. Now is the time to support vessel operators in making the shift, because when operators succeed, the entire industry benefits.