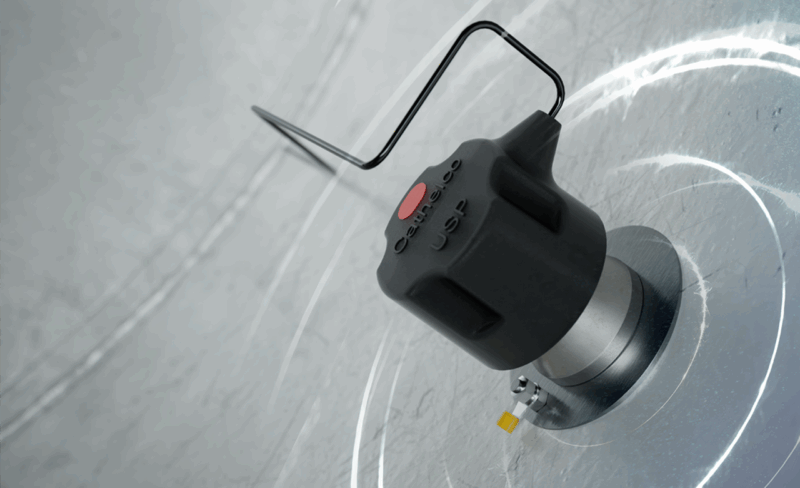

Cathelco enables wider hull-area protection with ultrasonic antifouling by waterproofing transducers for wet spaces

The cofferdam add-on waterproofs transducer installations so ultrasonic antifouling can be fitted in wet spaces, unlocking transducer placement behind previously unreachable hull sections and enabling broader hull coverage.

Why coverage gaps matter

There is a simple reality behind hull biofouling management: you do not need a fully fouled hull to lose performance. Localized fouling will still add drag, and drag translates quickly into higher fuel consumption and higher emissions.

The practical constraint on large vessels

For ultrasonic antifouling, achieving strong results starts with one practical requirement: being able to place transducers where they are needed to treat the entire waterside of the hull. On many large commercial vessels, that has not always been straightforward.

Large sections of the inner hull sit inside ballast tanks and other wet spaces, and traditional transducer installations require a dry environment. The result is that some ships have faced unavoidable coverage compromises, leaving parts of the waterside hull outside the treated area.

The solution: waterproof transducer installations in wet spaces

Cathelco has introduced a new cofferdam add-on to address that limitation and expand where its ultrasonic antifouling systems can be installed on large commercial vessels.

This enables installations in wet areas such as ballast tanks, bilges and other wet spaces. This in turn means transducer placement can be planned for the entire hull, rather than being dictated by where dry inner hull access happens to be available.

How the cofferdam works

The cofferdam itself is a steel housing welded to the inner hull at the planned transducer location. The transducer is mounted inside the sealed chamber and secured with a lid to maintain watertight integrity. Cofferdams are specified only where needed, so projects can add waterproofing for the particular transducer locations that require wet-space installation.

Discuss your application

To request a quotation or discuss cofferdam applications for your vessel or project, speak with the Cathelco team. We can review your vessel arrangement, identify suitable transducer locations, and advise on where cofferdams may be needed to support broader hull coverage.

How it works: patented ultrasonic technology for commercial vessels

Patented technology

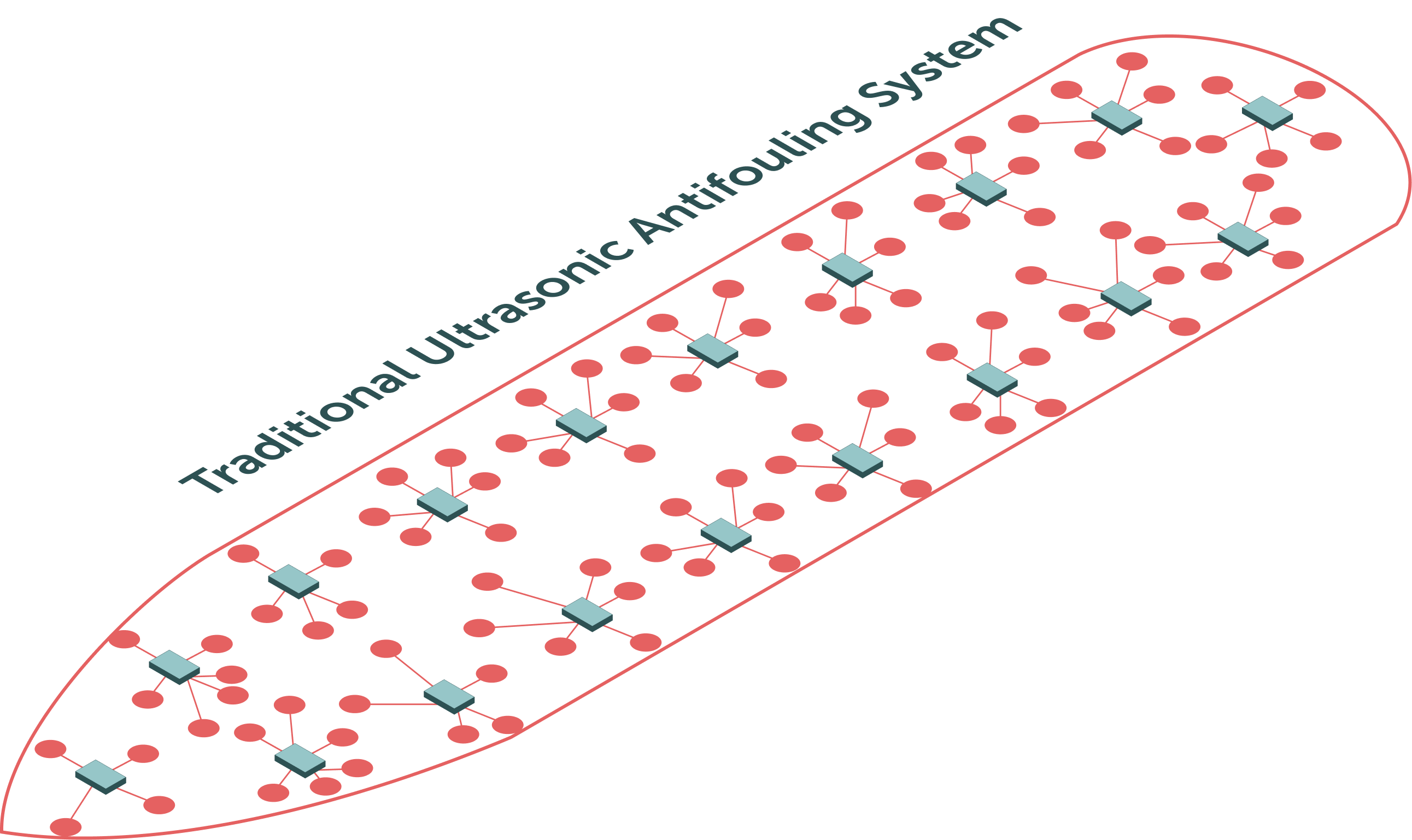

Cathelco’s USP DragGone™ system uses two key patented technologies—Heterodyning and Guided Wave—to create a highly effective antifouling solution. These technologies work together to disrupt biofouling organisms before they attach to the hull, even when your vessel is idling or operating at low speeds.

Heterodyning Technology

Multi-frequency protection for all waters

Generates multiple ultrasonic frequencies to target a wider range of fouling organisms compared to traditional ultrasonic antifouling systems.

Guided Wave Technology

Complete hull coverage with fewer transducers

Channels energy through the hull structure, ensuring protection over a larger area with 60% fewer transducers, reducing the need for additional hardware and installation complexity. The DragGone™ system is 40x more efficient than traditional ultrasonic antifouling systems.

DRIVE EFFICIENCY, REDUCE EMISSIONS

Why commercial vessels choose USP DragGone™ for unmatched 24/7 hull protection

With the USP DragGone™ system, your hull is protected from biofouling 24/7, even during extended idle periods in port. This means less time spent on hull cleaning, fewer logistical disruptions, and lower maintenance costs. Keep your vessel operational longer and reduce costly downtime.

DragGone™ helps extend the time between hull cleanings, reducing the risk of coating damage during cleaning operations. By keeping your hull biofouling-free, you’ll reduce the frequency of reapplications and minimize overall maintenance costs.

Our ultrasonic antifouling system offers a non-toxic, non-biocidal solution to biofouling, ensuring your offshore vessel remains compliant with environmental regulations. This means less transfer of invasive species and reduced environmental impact, making it easier to meet global sustainability standards.

Trusted by ship engineers and crew, the DragGone™ system operates silently and efficiently, ensuring no disruptions to your crew or equipment. It’s the ideal solution for commercial vessels, delivering advanced biofouling protection without compromising vessel performance or crew comfort.