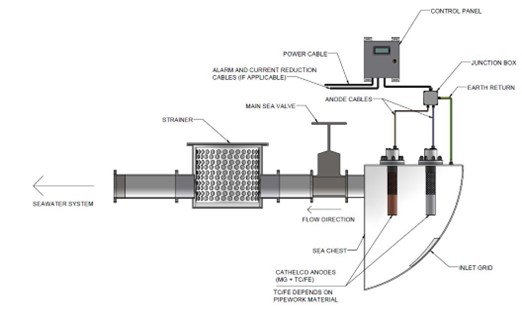

Cathelco® MGPS sea chest and strainer systems

With its long record of effectiveness and reliability, the Cathelco® system has become the most widely used seawater pipework antifouling system in the world. This success is the result of a combination of factors. Based on the electrolytic principle, providing continuous and reliable protection without the use of chemicals. Every system is custom designed for its particular application ensuring greater effectiveness.

Automatic operation – requires minimal attention and makes very little demand on crew time. Easy installation – anodes can be installed in sea chests or strainers at newbuilding or retrofit. Environmentally benign – does not involve the use of chlorine-based chemicals or other biocides. Approved by classification societies. Saves maintenance costs by eliminating pipework cleaning.

- The most widely used antifouling system in the world

- Easy installation

- Lifetime warranty

- Without MGPS manual cleaning is expensive and time-consuming.

- If fouling is not controlled in some cases complete pipework renewal may be necessary.

- Loss of operating time is massively reduced with an MGPS

- A vessel’s safety can be compromised if fouling blocks firefighting systems

- Systems are all individually designed based upon Faraday’s law to ensure a flow rate is dosed with a specific amount of copper ions per cubic meter an hour.

- Anodes are then sized based upon the area of installation and the ease of installation

- All installations come with mountings that adhere to class requirements in the area of installation

- Control panels are located to ensure that we regulate the copper ions per channel.

Anodes are fitted through the sea chest top plate using methods that adhere to class rules. By fitting anodes in the sea chest you will be treating the water used all over the vessel right at the source, this means pipework systems will have the maximum amount of protection throughout the vessel. Alternatively, if systems need to be installed prior to scheduled dry-docking, the anodes can be mounted in the seawater strainers. This also simplifies replacement when anode renewal becomes necessary.

Evac Lifecycle Management

For all our systems and solutions, we offer a comprehensive portfolio of services throughout the operational life of the delivered solution or equipment.