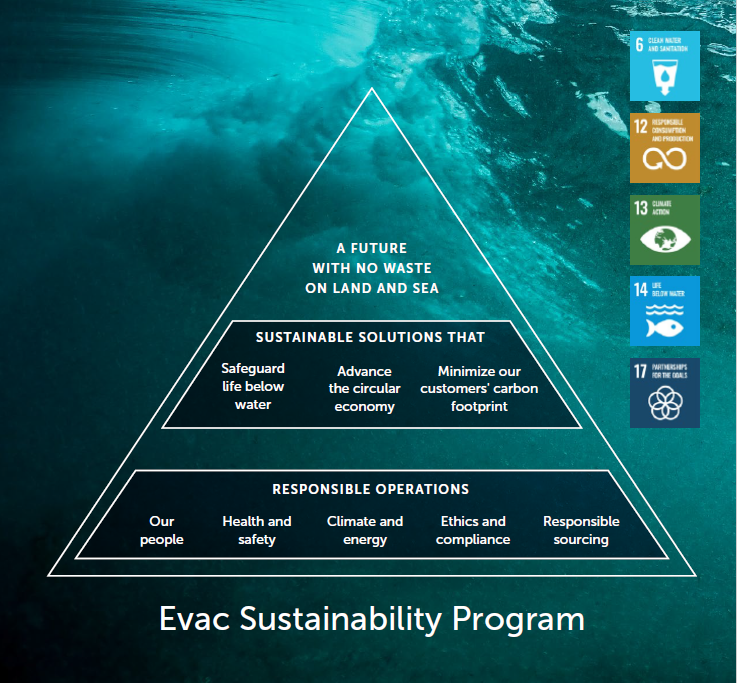

Striving for a future with no waste

Evac sustainability program

Evac’s approach to sustainability is strategically aligned with the key material topics and an ambitious goal to strive for a future with no waste. Guided by our sustainability program and our pledge to advance the UN Sustainable Development Goals (SDGs), we channel our efforts across the entire Evac Group.

Evac has anchored its operations in responsible business practices, focusing on the safety and well-being of its employees, climate and energy, and ethical operations across its own and supply chain operations.

Our ambitious sustainability agenda is not just about minimizing negative impacts but maximizing positive contributions to people, the planet, and prosperity. Moreover, we aspire to catalyse industry-wide transformation by sharing our expertise and driving broader shifts toward sustainability within the maritime and building sectors.

The UN SDGs we can influence the most

Nothing to waste

You can read more about our sustainability approach in the sections about Sustainable solutions and Responsible business practices and about our governance model on Sustainability governance and stakeholder engagement.