Rosewood London: How Vacuum Plumbing Enabled a Heritage-Sensitive Luxury Hotel Conversion

When design meets preservation, every detail matters. The Chancery Rosewood project shows how architects can reimagine historic fabric without sacrificing comfort, layout, or sustainability. If you design conversions, this use case reveals how a listed landmark beat structural limits—and what that unlocks for adaptive reuse.

Why this matters beyond one hotel

It’s tempting to regard Chancery Rosewood as a one-off, but the underlying logic is transferable. The constraints that doomed gravity here (deep floorplates, below-sewer conditions, protected fabric) are common across office-to-residential and office-to-hospitality conversions. Consider London’s Zedwell Underground Hotel, a disused car park turned into 207 rooms below sewer level: the same high-level routing to HQE plants avoided excavation and delivered multi-million-liter annual water savings. The method repeats because the physics repeats.

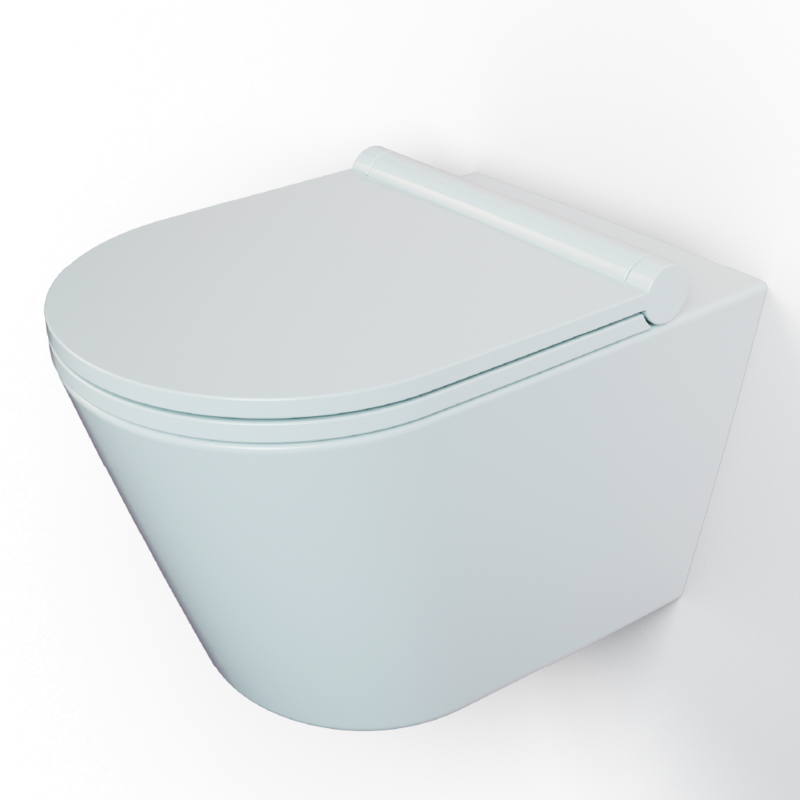

That transferability extends to aesthetics. In programs that must retain a specific wall-hung bowl design, Evac VacuConvert™, a gravity-to-vacuum bridge introduced in September, allows selected conventional bowls to join a vacuum network without changing the visible design. For brands and heritage interiors where the look is non-negotiable, that is a pragmatic on-ramp to system-level benefits.

“You don’t sell vacuum as a novelty,” Trieu says. “You show how it removes constraints. That’s what owners, architects, and contractors feel on day one.”

A new default for difficult buildings

Architects often talk about design freedom as a matter of form and finish. Rosewood suggests a more literal freedom: freedom from the slope. When you stop asking where the water can fall and start asking where the room should be, the plan clears. Heritage stays intact. Guest comfort improves. The OPEX softens. The program steadies.

That is why this project reads like a proof point for a new default in difficult buildings. Don’t fight gravity; bypass it. Route small. Route high. Centralize the mechanics. And where a particular bowl must stay, bridge it. In the portfolio view (multiple assets, phased upgrades, tenant-in-place constraints) those are not just engineering choices; they are business choices that compound across time.

What to take forward

- Treat gravity as an option, not a law. If slab cutting is unacceptable or riser counts are strangling the plan, vacuum is likely the better default.

- Design at high level. Put mains in the ceiling and complexity in the plant; your plans and your schedules will thank you.

- Think portfolio, not one-off. A repeatable kit of parts: vacuum interface units + Optima® toilets + HQE plant builds muscle memory across projects.

- Bridge when you must. Where brand or heritage requires a particular bowl, VacuConvert™ is the practical path to system-level gains without visible change.

Heritage fabric preserved, layouts unlocked, and quieter operation came from a simple kit of parts: small-bore mains at high level, vacuum interface units, a central HQE plant, and Optima® low-water toilets. Where a specific wall-hung bowl must be retained, VacuConvert™ bridges it to the vacuum network without changing the visible design.

Get to know the products

VACUCONVERT Brief for stakeholders