Evac EcoScreen

Inorganic-based materials can accumulate over time and decrease wastewater treatment efficiency or even cause clogging or damage over time in wastewater treatment systems. Therefore, the wastewater usually needs to be screened before the main treatment.

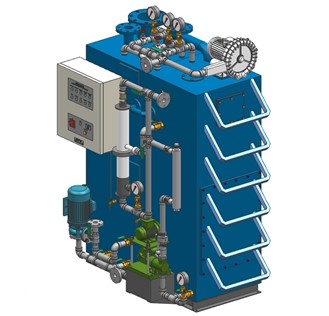

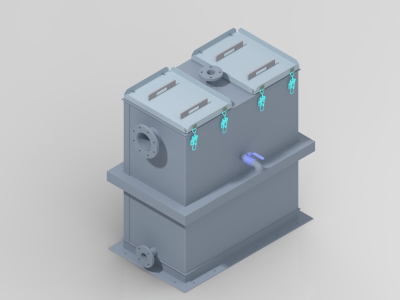

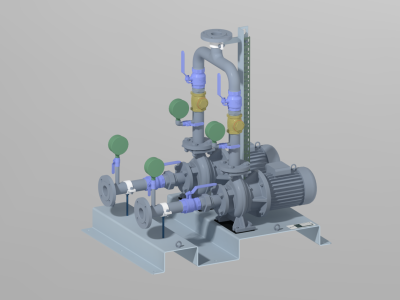

The Evac EcoScreen screening system is used to pre-purify wastewater from these unwanted materials. Due screening unit in the AWP system, the sludge amount in MBR/MBBR unit is decreased and more importantly, the fouling rate of the membranes is decreased (MBR systems) and the risk of clogging is reduced.

- Prepurifies wastewater from unwanted materials

- Decreases the fouling rate of the membranes

- Reduces the risk of clogging

- Great reduction in potential damage and clogging in the wastewater treatment system

- Environmentally friendly, free of chemicals

- Robust and easy to operate

| Evac EcoScreen Model | Max. Flow Capacity (m3/h) | Number of Screens | Screened water tank volume (m3) |

| EcoScreen 200 | 18 | 1 | 0,6 |

| EcoScreen 200T | 36 | 2 | 1,0 |

| EcoScreen 300 | 36 | 1 | 1,1 |

| EcoScreen 300T | 72 | 2 | 1,8 |

The EcoScreen separates and screens the coarse and fibrous materials out of the wastewater via dewatering screw to plastic foil bags that can then be treated further onboard or transported to shore. Screened water can be pumped then safely to the sewage treatment onboard. BOD loading in wastewater is decreased by up to 30 %, helping to reduce the organic load that the following units must treat.

Evac Lifecycle Management

For all our systems and solutions, we offer a comprehensive portfolio of services throughout the operational life of the delivered solution or equipment.