Evac MBR

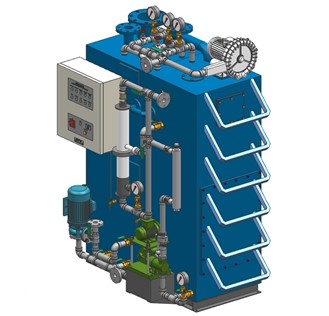

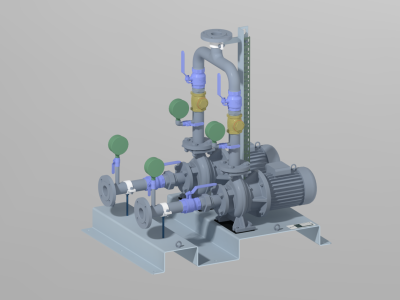

Evac MBR (Membrane BioReactor) is an advanced biological wastewater treatment plant suitable for all vessel types ranging from small yachts to large cruise ships. The MBR plant handles all black (sewage) and grey waters from galleys, sinks, showers, and laundry facilities, generating good quality effluent in one step without the need for further post-treatment steps. The MBR can incorporate an optional additional nutrient removal step.

- Wastewater treatment plant for all passenger vessels

- Treats all wastewater streams to current standards – and beyond

- The heart of an advanced wastewater process

- Completely automatic and easy to maintain and control.

- High-quality disinfected effluent without the use of chemicals

- Extremely low running costs and minimal energy consumption

- Completely modular and highly customizable system.

- IMO MEPC.227(64) compliant

| EVAC MBR MODEL | Max Hydraulic load (m3/day) | Max BOD5 load (kgO2/day) | Dry Weight (kg ±10%) | Wet Weight (kg ±5%) | Dimensions L x W x H (mm) |

| EVAC MBR 7K | 7,5 | 4 | 1600 | 3900 | 2281 x 1914 x 2365 |

| EVAC MBR 15K | 15 | 8 | 2100 | 5700 | 2322 x 2228 x 2399 |

| EVAC MBR 22K | 22 | 11 | 2300 | 7000 | 2575 x 2366 x 2399 |

| EVAC MBR 30K | 30 | 15 | 3000 | 9600 | 2778 x 2595 x 2399 |

| EVAC MBR 45K | 45 | 23 | 3400 | 12000 | 2995 x 2845 x 2491 |

| EVAC MBR 70K | 70 | 35 | 3800 | 18200 | 4390 × 2289 × 2200 |

| EVAC MBR 95K | 95 | 50 | 6400 | 24800 | 5690 x 2469 × 2200 |

| EVAC MBR 120K | 120 | 60 | 7400 | 31300 | 5890 x 2890 × 2200 |

| EVAC MBR 145K | 145 | 75 | 8500 | 37300 | 6898 x 2969 × 2200 |

Evac MBR larger customized sizes available upon request

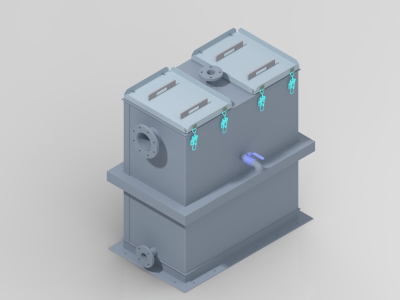

The MBR tank contains suspended biomass and membrane filtration modules. The mixed pre-treated wastewater is fed to MBR where the biomass oxidizes the organic matter present in it. Treated water from MBR tank is sucked through permeate pipe to a dedicated tank from which it can be pumped overboard

Evac MBR is certified according to IMO MARPOL MEPC 227(64) with nutrient removal, thus fulfilling the amendments to Chapter 4.2 of MEPC 227 for passenger ships in restricted areas such as the Baltic Sea. The Evac MBR units also fulfil the requirements of the Rhine River certification, and it is possible to manufacture them according to U.S. Coast Guard (USCG) regulations.