Drainage solutions for cold storage and warehouse facilities

Overcome condensate drainage and slab penetration issues and get significant water savings for your cold storage, warehouse and other controlled environment facility projects with Evac´s vacuum technology

Cold storage and warehouses

Cold storage warehousing is storing sensitive goods like food, medicines and botanicals at a specific temperature range to maintain their quality and shelf-life. Cold storage facilities have temperatures normally ranging from 33° to 55° F (0° to 15°C), while freezing rooms can go as low as -100° F (-40°C). This also sets higher requirements for industrial drainage solutions compared to common warehouses, and vacuum technology can help with them.

Typical drainage solutions for cold storage facilities consists of vacuum piping network, vacuum collection system or vacuum center and fixtures or interface units. With vacuum drainage, you can use typical gravity fixtures such as sinks, mop basins and drinking fountains. You can also easily tie the black water areas, including restrooms and other fixtures, into the vacuum system for a complete wastewater collection and drainage solution.

Drainage solution offering cost savings and easier installation

Evac´s vacuum technology allows wastewater to be transported around obstacles, overhead or horizontally without a continuous slope — pipes can be routed upwards, to enable very high lifts depending on specifications. Pipes used in vacuum drainage systems are significantly smaller than traditional gravity piping network, making design and installation simpler and more flexible. Vacuum systems also negate the need for traditional stack design as vacuum drainage pipework can rise to a high level with small bore piping network.

Compared to traditional gravity plumbing, Evac´s vacuum drainage solution can offer cost savings on both new and renovation projects as slab penetration and multiple pits for long runs can be avoided and technology can be built with smaller pipe diameters. Expandability can also be added to any system design to accommodate future expansion or additions, making remodeling warehouse facilities quicker and easier.

What is a vacuum technology?

Vacuum drainage is a complete plumbing system that follows principles more robust than a conventional gravity drainage system. Vacuum generation units create negative pressure in the system, and condensate water is transported through an overhead piping network as air is withdrawn rather than wastewater slowly draining by gravity. The vacuum also creates the opportunity for water reuse, making the technology a sustainable choice.

Improve hygiene in restroom and sanitation facilities with vacuum toilets

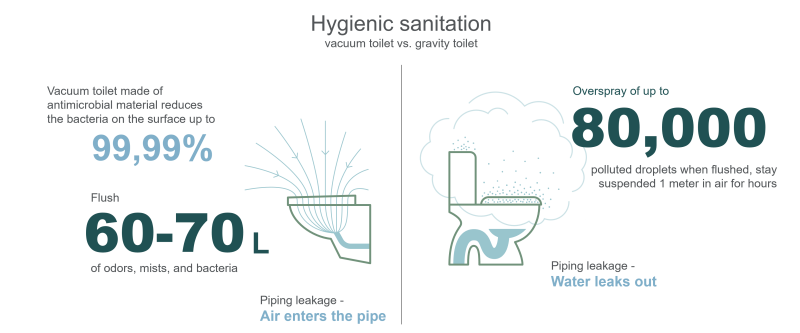

You can also add Evac´s vacuum toilets into the system. By taking advantage of the vacuum toilet flushes you can see 80-90% water savings, and a more hygienic facility.

Vacuum toilets allow the suction of 60 liters of air during a flush, suppressing the risk of contaminated mist, odors, and bacteria. Minimal water usage also means less chance for bacteria to spread, which makes it a particularly sound choice for high-traffic buildings with public restrooms. Toilets are also available with antimicrobial material, which reduces the bacteria on the surface by up to 99,99%.

See all our products for cold storages and warehouse

Contact us for more information

Whether you need any products, systems, spares or other services, you will find the contact details of your local team on our Contact us -pages.

Land-based customer segments

Our vacuum systems provide a reliable, gravity-free wastewater collection for the lifetime of the building. Read more about our offering for different building applications.